What is a Good Tension for Screen Printing?

Screen printing is a very accurate art; many factors affect this process, and one of the greatest is screen tension. A proper tension on a screen allows good printing quality, durability of prints, and maintenance of print consistency. But what is good tension for screen printing? This article will address the ideal tension levels of screens, how the tension level can be measured and maintained, and why that is important in screen printing.

Table of Contents

Understanding Screen Tension in Screen Printing

What is Screen Tension?

Screen tension describes how tight the mesh is on the frame. It thus controls the ink transfer behavior and print distortion. Newtons per centimeter (N/cm) measure the screen tension, which affects registration, ink flow, and print quality.

Why is Proper Screen Tension Important?

- Sharp, Clean Prints – Reduces ink smudging and maintains design integrity.

- Consistent Ink Flow – Ensures even ink distribution for professional results.

- Extended Screen Life – Prevents premature wear and tear on mesh.

- Improved Registration – Keeps multi-color prints properly aligned.

- Reduced Ink Consumption – Optimized tension leads to more efficient ink use.

Ideal Screen Tension Levels for Screen Printing

An ink’s best tension level depends on the mesh count and type of screen being used. Following is a general guide to the recommended tension levels:

| Mesh Count (Threads Per Inch) | Ideal Tension (N/cm) |

|---|---|

| 80-110 TPI | 15-20 N/cm |

| 125-160 TPI | 20-25 N/cm |

| 180-230 TPI | 25-30 N/cm |

| 250-305 TPI | 30-35 N/cm |

Higher tension means less tension, which is going to squash a sharper print but can break the screen quickly.

How to Measure Screen Tension

Tools for Measuring Tension

- Tension Meter – A device that measures the Newton/cm value accurately.

- Digital Calipers – Used to check mesh stretch consistency.

- Visual Inspection – Checking for wrinkles, sagging, or overstretching.

Step-by-Step Guide to Measuring Tension

- Place the tension meter on the screen surface.

- Check the reading at multiple points.

- Adjust or re-stretch if the tension is inconsistent.

- Record measurements for consistency.

How to Maintain Proper Screen Tension

1. Pick Up Quality Frames

Aluminum frames are better since they retain tension for a longer period, in contrast to wooden ones, which may warp over time.

2. Use Retensionable Frames

Retensionable frames allow you to adjust tension as required, thus extending the screen’s life.

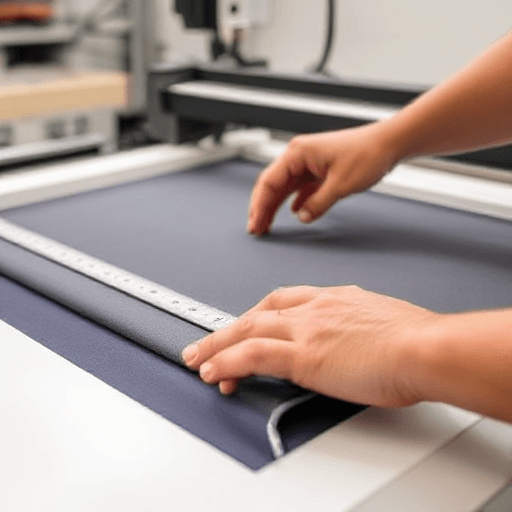

3. Stretch Screens Properly

- Use a professional stretching system.

- Let the mesh rest after initial stretching to lower future relaxation.

- Make sure to stretch uniformly; otherwise, you will create weak areas.

4. Re-tension Screens Regularly

With usage over time, the screen will lose tension. Re-tensioning is, however, very important for keeping print quality.

5. Store Screens Correctly

Avoid extremes of humidity and temperature variations that may affect tension stability.

Conclusion

Making sure you get the tension right for screen printing is key for attaining high-quality outputs and consistent screen prints. Observing the recommended standard tension, along with the appropriate measuring tools and keeping tension up through time, can give a great advantage to the screen printer by enhancing print accuracy as well as longevity of the screen in service. Whether you are a beginner or a seasoned professional, perfecting the skill of tensioning screens gives you better prints with more efficient use of your time.

FAQs

What happens if screen tension is too low?

Low tension leads to blurry prints, uneven ink transfer, and poor registration.

Can screen tension be too high?

Yes, excessive tension can cause mesh breakage and reduce screen longevity.

How often should I check screen tension?

It is best to check tension before every print job and after cleaning screens.

Do different types of ink require different tension levels?

Yes, higher tension suits thicker inks such as plastisol, while moderate tension favors water-based inks to lodge correctly.