3D Printing with Salmon Skin

The investigation of 3D printed salmon skin enters a much deeper space, a space where sustainability and creativity converge into design. It takes a common waste product, typically thrown away, and turns it into a material one can work with for the fabrication of 3D printed objects-lively ones in a very complex, intricate manner. The surface of salmon skin, with its firm texture and distinctive patina, offers an attractive but entirely fresh gaze for enriching designs. Salmon skin has an attractive texture and countless possibilities. In addition to being one of the most decorative materials, salmon skin makes a strong statement in 3D printing projects as being resourceful and environmentally conscious, being sustainable design principles. This unconventional material opens the doors for designers and makers into entirely new dimensions for sustainable fashion, art, and product design, which push the limits of conventional fabrication methods. The incorporation of salmon skin into 3D printing not only celebrates the beauty of repurposing materials but also highlights the need for innovation and sustainability in the design and manufacturing future.

Table of Contents

What Causes Salmon Skin 3D Printing?

Salmon skin 3D printing is an innovative application that merges sustainability with creativity in the world of additive manufacturing. The process of creating 3D prints using salmon skin involves several key steps.

1. Material Sourcing and Preparation:

This is the first stage of salmon skin from the fishing industry. Skins have to be processed taking away impurities to make them usable for 3D printing. This is the crucial part of preparing the right and good material.

2. Filament Production:

Processed salmon skin is changed into a filament meant to fit inside a 3D printer. This filament might contain a combination of salmon skin along with other materials to improve its characteristics of printing and durability.

3. Printing Process:

Every layer of the salmon skin filament is laid down by the 3D printer during the printing according to the specifications of design generated digitally. The distinct textures and characteristics of salmon skin make the product aesthetically unique.

4. Finishing and Post-Processing:

Post printing, the 3D printed objects may be subjected to finishing steps aimed at enhancing their appearance and durability. This may involve sanding, polishing, or coating in order to achieve the desired final look.

5. Environmental and Creative Impact:

The 3D printing of salmon skin is not only a matter of sustainability because it recycles a waste product into a novel creative territory for designers and artists, but also potentially incorporates new natural textures and colors from the fish skin, which could make spectacularly impressive, environmentally aware, and 3D printed objects.

Thus, this entire process of salmon skin 3D printing involves very meticulous preparation of the material, filament production, printing, and finishing. This new methodology promises sustainable applications that are also very different in aesthetics in the area of additive manufacture.

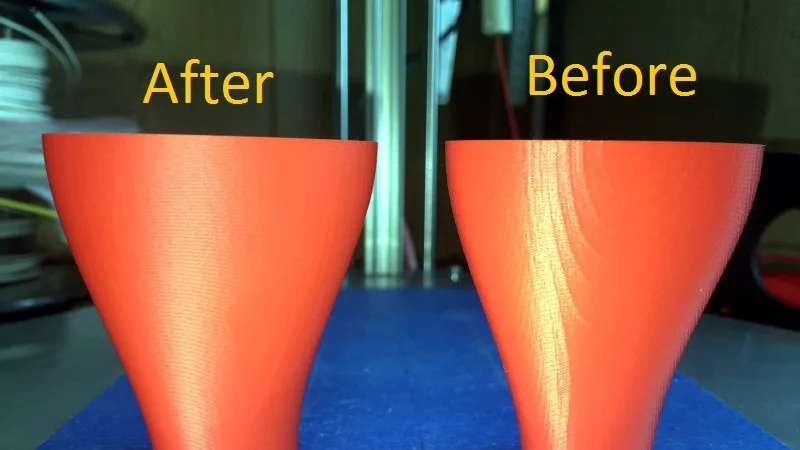

How to solve the salmon skin effect in 3d printing?

To avoid the occurrence of the salmon skin effect in 3D printing, which defines the property whereby the surface looks much like the skin of a salmon, some of the solutions to apply are:

- Adjust Printing Parameters:

- Layer Height: Decrease the layer height in your 3D printing settings. Finer layers can help smooth out the surface and reduce the visibility of the texture.

- Print Speed: Slowing down the print speed can also improve the surface finish by giving each layer more time to cool and solidify properly.

- Temperature Control:

- Ensure that the temperature settings for the extruder and heated bed are optimized for the specific filament material you are using. Maintaining consistent temperatures can help prevent texture variations.

- Calibrate Extrusion:

- Properly calibrate the extrusion multiplier and flow rate to ensure that the right amount of filament is being extruded. Over-extrusion can contribute to the salmon skin effect.

- Check Cooling System:

- Adequate cooling is essential during 3D printing to solidify each layer quickly. Make sure that your printer’s cooling system is functioning properly and adjust the fan settings if needed.

- Upgrade Filament Quality:

- Using high-quality filament with consistent diameter and composition can help achieve smoother and more uniform prints, reducing the appearance of the salmon skin effect.

- Post-Processing Techniques:

- Consider post-processing techniques such as sanding, polishing, or applying a smoothing agent to the printed object to improve the surface finish and minimize texture variations.

- Experiment with Settings:

- It may be necessary to experiment with different settings and configurations to find the optimal combination for your specific 3D printer and filament. Keep track of changes and their effects on print quality.

With these solutions and adjustments, salmon skin effects will be reduced or eliminated in the 3D prints to produce a smoother, more visually aesthetic finish.

Salmon Skin as a Sustainable Material:

Renewable Resource:

Traditionally, salmon skin is a by-product rather than a conventional material, thus making it quite sustainable.

3D printing enthusiasts and designers owe this practice of being eco-friendly to their activity of reusing salmon skins, which would otherwise be wasted.

Unique Qualities:

Salmon skin has very unique textures, patterns, and flexibility; hence, it is also a material that can be quite exciting in both artistic and functional applications.

Durability and water resistance add to its natural properties that make it all the more attractive for its use in 3D printing projects.

Applications of 3D Printing with Salmon Skin:

Fashion and Wearable Technology:

The salmon skin is being experimented with by designers to manufacture avant-garde fashion items, accessories, and wearable technology.

This particular texture and hue of salmon skin lend elegance and sustainability to fashion design.

Art and Design:

Artists and designers are using salmon skin in sculpture, home décor, and monumental art installations.

Salmon skin serves well in producing very complex and striking pieces by means of 3D printing.

Challenges and Innovations:

Material Processing:

Salmon skin must be processed, applying certain 3D printing techniques to obtain better texture and structural integrity, which is rather compromising.

Innovations in material preparation and treatment methods need to be considered in order to enhance the performance of salmon skin within the additive manufacturing arena.

Environmental Impact:

Sustainable materials such as salmon skin are in keeping with the increasing attention on sustainability in design and manufacture.

The challenges attracting maximum attention, however, include scalability, affordable processing, and waste reduction on the path to the widespread acceptance of salmon skin in 3D printing.

Future Prospects and Sustainability:

Collaborative Efforts:

Collaborating across the fields of design, research, and industry can push innovation, creating new opportunities for the use of salmon skin in 3D printing.

Sustainability in Design:

The introduction of materials such as salmon skin into the design process leads towards more environmentally sound and socially responsible manufacturing practices.

Conclusion:

3D printing with salmon skin offers opportunities and technologies for sustainable creativity. Designers and enthusiasts are indeed exploring the new frontiers of additive manufacturing using the unique properties of this natural material and are setting the ground for a more sustainable and creative 3D printing future.

FAQs about 3D Printing with Salmon Skin:

What are the benefits of using salmon skin in 3D printing?

Utilizing salmon skin in 3D printing supports sustainability by reusing a waste material, gives unique texture to 3D printed objects, and furthers the exploration into Eco-friendly materials in manufacturing.

Is the salmon skin 3D print Eco-friendly?

Yes, the process of salmon skin is deemed environmentally friendly due to its recycling of a waste material, propagation of sustainability within manufacturing, and encouragement for using natural materials within 3D printing applications.

How can filament quality impact the salmon skin effect?

Poor-quality filament with inconsistent diameter or composition may create a corresponding effect in the print due to texture discrepancies. On the essence, good-quality filament makes the print smooth and uniform with diminished salmon skin effect.

How can calibration errors be corrected to reduce the salmon skin effect?

Having the extrusion multiplier set right and calibrating flow rate and other settings of the printer will help in achieving maximum uniformity in extrusion and deposition of layers, thereby helping reduce the salmon skin effect on the printed piece.