Screen printing is a prevalent process of placing designs, patterns, and images onto cloth. Screen printing can be executed on various fabrics, each of which offers varying properties that can affect the quality and outcome of the printed design.

Fabric selection is a key element of the art and science of screen printing. Choosing the right fabric can significantly impact the quality, durability, and overall outcome of the printed design. From cotton to polyester and various blends, each fabric type offers unique characteristics that influence how ink adheres, colors appear, and prints withstand wear and tear. An understanding of the properties of different fabrics and how they react to the screen printing process is essential to achieve bright, long-lasting prints that meet the desired aesthetic and performance specifications. In this article, we venture into the world of fabric selection for screen printing, such as the types of fabrics most commonly used, fabric selection considerations, and tips on achieving the best results on different types of fabric.

Table of Contents

Understanding Screen Printing Fabrics

Screen printing fabrics are pivotal components in the process of screen printing, playing an integral role in specifying the quality and resilience of the printed image. Screen printing fabrics are the medium on which the ink is printed, and they influence color vivacity, stickiness, and durability of the print. Familiarity with the characteristics of different screen printing fabrics is essential in order to achieve desired results and ensure the success of the printing business.

Selecting the right fabric is a crucial aspect of achieving the desired result in screen printing. The fabric employed plays a significant role in determining the quality, appearance, and longevity of the printed image. Below are some of the most significant reasons why selecting the right fabric for screen printing is crucial:

- Print Quality:The substance that the fabric is constructed from directly affects print quality. Every fabric material will possess its own level of absorbency, texture, and smoothness, affecting how ink adheres to it and how crisp the resulting print will be. Choosing an ink and printing process that are suited to the fabric material can result in accurate, highly detailed prints in rich color.

- Color Vibrancy: Fabric does not respond uniformly to the ink, impacting color brightness and quality of colors of the print. Some fabrics positively impact the vibrancy of colors, and others may dull or change the colors. Selecting a fabric to be used with that will complement the desired color scheme can make the printed design appear as intended, with rich and realistic colors.

- Durability: The longevity of the printed design highly depends on the fabric that is being used. Fabrics with good colorfastness and resistance to fading, shrinking, or stretching will make the quality of the print last long. Choosing a durable fabric implies that the design will remain bright and intact despite several washes or extended use.

- Adhesion and Ink Absorption: The absorbency and texture of the fabric control how well the ink is absorbed and spreads on the surface during printing. Fabrics that have the perfect level of absorbency can produce even coverage and clear details on the print. Proper absorption of the ink prevents bleeding or smudging and leaves clean, crisp prints.

- Versatility and Application: Different materials are applied for specific purposes based on their nature. Cotton, for example, can be applied for products with soft texture like t-shirts, while polyester can be applied because of its durability in outdoor signs. The knowledge of the nature of each material allows one to make choices that suit the specified purpose and conditions of application of the printed materials.

Types of Fabrics Used in Screen Printing

1. Cotton Fabric:

Cotton is among the most sought-after fabrics for screen printing due to a variety of characteristics that make it extremely well-suited to screen printing. The following are some of the key reasons for the employment of cotton in screen printing:

- Absorbency: Cotton materials have great absorbency, which makes it simple for them to absorb and hold the ink while printing. This results in color intense and long-lasting prints because the ink settles in the fibers of the material.

- Softness: Cotton has a soft and pleasant touch, which makes it a choice of preference for clothes and fabrics that directly come in contact with the skin. Softness contributes to the overall quality and comfort of the printed products.

- Breathability: Cotton is a permeable material in which air will pass through the fabric, making it comfortable to wear in various weather conditions. Breathability of cotton is especially important when creating clothing such that the prints are not compromising comfort.

- Durability: Cotton fabrics are reasonably durable and able to withstand frequent use or washing, and cotton fabrics are suited for screen printing on items subject to frequent use or washing. The cotton fabric maintains the printing color even through multiple washings.

- Versatility: Cotton is a highly flexible material that can be utilized for a wide range of screen printing applications, from t-shirts, hoodies, and tote bags to other various products. The flexibility of the material makes it a favorite for most screen printers who desire to create high-quality prints on many products.

- Color Retention: Cotton has good color retention properties, with the fabrics being able to retain the colors applied to them quite well even after a long time. This allows the prints on cotton fabrics to be kept bright and colorful, remaining visually appealing even after washing several times.

- Environmental Friendliness: Cotton is biodegradable and natural in fiber, thus a friendly option to the environment for screen printing. It is sustainable, renewable, and can easily be recycled or composted once its life cycle ends.

The use of cotton fabric in screen printing offers many benefits that help ensure the quality and success of the printing process. Some of the key benefits of using cotton fabric for screen printing are listed below:

- High Absorbency:Cotton fabric has a high absorbent ability, and it can easily absorb and hold ink during the printing process. This delivers rich and long-lasting prints with sharp details and color.

- Color Vibrancy: The cotton fibers can very easily absorb the ink’s pigments and retain them, causing the printed image to have intense and rich colors. Rich and life-like colors are seen on cotton fabric, making the printed products have more visual impact.

- Soft Feel: Cotton is soft to the touch with a pleasant surface, and so it is best suited for the production of apparel and textiles, which come directly into contact with the skin. Printed pictures on cotton fabric offer a smooth pleasant touch, giving the final product a better quality.

- Breathability: Cotton is a breatheable fabric by which the airflow is allowed, and thus cotton can be easily worn under any climatic conditions. The breathability gives temperature control and comfort while wearing printed cotton apparel.

- Durability: Cotton fabrics are very resilient and can endure day-to-day wear and washing without the quality of the print diminishing. Prints on cotton fabric remain sharp and bright even after multiple washing sessions, guaranteeing durability and longevity.

- Versatility: Cotton is a versatile cloth that can be used in numerous screen printing items, including garments, accessories, home fabrics, and many others. Its versatility makes it the printer’s top preference for making high-quality prints on various products.

- Environmentally Friendly: Cotton is a natural and biodegradable material that is an environmentally friendly choice for screen printing. It is sustainable, renewable, and when it reaches the end of its life cycle, it can be recycled or composted, reducing the environmental impact of printed products.

- Easy to Print On: Cotton allows for an even and smooth printing surface, making it simple to achieve precise and detailed prints. The cotton fibers hold the ink well, making the prints clean and professional.

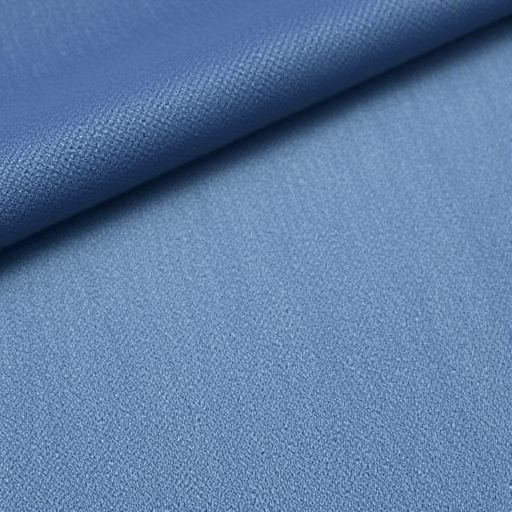

2. Polyester Fabric:

Polyester fabric offers a host of advantages and properties that enhance it as one of the go-to fabrics of screen printing. A few of the most essential advantages of using polyester fabric for screen printing include:

Environmentally Friendly Options: Polyester can further be manufactured out of recycled components, offering an environmentally friendly alternative to traditional environment-conscious printing efforts. Recycled polyester reduces production and consumption from harming the ecosystem, giving environmentally friendly screen printing an alternative it needs.

Durability: Polyester is a highly durable synthetic fabric that is resistant to stretching, shrinking, wrinkles, and abrasion. This durability ensures that prints on polyester fabric maintain their quality and appearance over time, even after repeated wear and washing.

Colorfastness: Polyester fabric enjoys superior color fastness properties such that printed color does not change or fade due to sunlight exposure, washing, and general usage. Polyester, therefore, offers a perfect platform for designs calling for color persistence over time.

Easy Care: Polyester is easy to care for and doesn’t take much maintenance. It is wrinkle-free and dries fast, making it a simple option for clothing and fabric that needs to maintain its appearance with little effort.

Smooth Texture: Polyester is smooth and even in texture, providing a uniform surface for printing. Smoothness is ideal for creating very fine and detailed prints, best suited for designs that require high definition and clarity.

Moisture-Wicking: Polyester is a moisture-wicking fabric that draws water away from the skin, making the wearer dry and comfortable. The property is beneficial for sportswear, sportswear, and exercise clothing.

Vivid Prints: Polyester fabric also has excellent ink adhesion, enabling bright and clear prints with high color saturation. The fabric’s smooth finish and material color-holding property ensure printed images have a vivid, eye-catching effect.

Versatility: Polyester is a very flexible material that can be printed on a wide range of screen printing applications, like sportswear, outdoor advertising signs, bags, and promotional items. It is resistant and colorfast enough to allow for designs that require longevity and toughness.

Polyester fabric is to be credited for vivid and long-lasting prints in screen printing due to its certain features that ensure the quality and longevity of the printed image. The following discusses how polyester fabric makes prints vivid and long-lasting:

- Adhesion of Ink: Polyester fabric also offers a non-absorbent, smooth surface upon which ink will adhere well and flow well when printing. This results in fine and detailed prints with rich color and intense color saturation.

- Color Retention: Polyester fabric has good color retention properties, i.e., the printed colors remain bright and vivid even after frequent washing and prolonged use. The fabric can absorb pigments from the ink, maintaining the print colors natural and free from easy fading.

- Durability: Polyester is a robust man-made material that withstands stretching, shrinking, wrinkling, and abrasion. Polyester fabric prints can withstand constant wear and washing without fading or losing their quality and color, thus are long-lasting and resistant.

- Resistance to Fading: Polyester material is resistant to fading due to sunlight and unfavorable environmental factors. This helps maintain the intensity of the printed colors for a long time, making the design look aesthetically pleasing and vibrant.

- Rapid Drying: Polyester material dries quickly, so the printed image sets and cures well throughout the screen printing process. Rapid drying time improves the crispness and sharpness of the print, creating clean and sharp designs.

- Consistent Texture: The uniform texture of polyester fabric provides a flat surface for printing, allowing precise and detailed prints. The smooth surface of the fabric guarantees that the prints are clear and sharp, giving quality to the finished printed items.

- Versatility: Polyester cloth is versatile and can be used on a number of screen printing applications, including apparel, accessories, signs, and promotional items. Its ability to produce vibrant and long-lasting prints makes it a bestseller for prints that require durability and color retention.

3. Blends (Cotton-Polyester, Tri-Blends):

- Cotton-polyester and tri-blend fabrics offer a combination of the strengths of both fabrics.

- These blends can provide a combination of softness, strength, and color brightness, and they are good for screen printing as general-purpose substitutes.

4. Rayon Fabric:

- Rayon is a semi-synthetic cloth which is light, airy, and drapey.

- It can be used for screen printing in garments that require flowing and softness, such as dresses, blouses, and scarves.

5. Linen Fabric:

- Linen is a natural fiber with the quality of being breathable, strong, and textured-looking.

- It can be screen printed onto items like home decor, tablecloths, and apparel where a distressed or natural effect is needed.

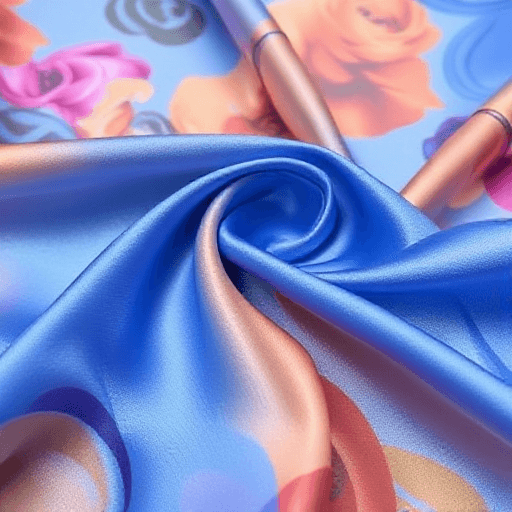

6. Silk Fabric:

- Silk is a costly and delicate material that can be screen printed on for high-end clothing, scarves, and accessories.

- Screen printing silk must be treated differently because silk is a very fragile fabric with a smooth finish.

7. Canvas Fabric:

- Canvas is a durable and resistant fabric that is widely used for screen printing on tote bags, backpacks, and other heavy-duty products.

- It possesses a tough surface that can withstand the ink application and washing with ease.

8. Denim Fabric:

- Denim is a tough and resistant fabric that is usually used for screen printing on jeans, jackets, and other denim apparel.

- Screen printing on denim can produce an original and rugged appearance with a distressed or vintage finish.

Factors to Consider When Choosing Fabric for Screen Printing

Fabric Texture :

What influence does fabric texture have on the printing outcome?

Fabric texture plays a role in determining the printing outcome in screen printing. Fabric texture refers to the surface characteristics of the material, including smoothness, roughness, weave pattern, and overall feel. These are some of the ways that fabric texture influences the printing outcome:

- Ink Adhesion: The smoothness of the material determines how much the ink adheres to the surface. Smooth materials provide a level, more uniform surface for ink to adhere to, resulting in sharp and crisp prints. Textured or rough materials may have surface elevation inconsistencies that affect ink adhesion and result in less precise prints.

- Level of Detail: The smoothness or texture of the fabric plays a crucial role in determining the level of detail possible in the print. Smooth, fine-textured fabrics allow fine and intricate designs to be printed with great accuracy. Textured fabrics can give depth and volume to the print but can limit the sharpness of fine details.

- Color Saturation: The texture of the fabric can influence the saturation of color in the print. Smooth materials will usually result in an even surface to transfer ink, allowing for colors to appear more saturated and rich. Textured material is likely to accept ink unevenly, which will influence the strength and consistency of colors in the print.

- Print Clarity: The type of fabric used influences the crispness and clarity of the printed design. Smooth and even textures will produce sharp, crisp prints with clear details and edges. Textured fabrics can produce a diffused or softer appearance based on the texture.

- Texture Contrast: The material’s texture can create visual contrast in the printed item. Textured materials can interact with the ink to create unique effects, e.g., distressed or vintage. By deliberately choosing materials with specific textures, printers can enhance the visual attractiveness and character of the printed items.

- Fabric Absorbency: The fabric texture can also impact the absorbency characteristics of the fabric. Various textures can absorb ink at different rates, influencing the way colors mix and interact on the surface. Knowing the absorbency of the fabric texture is crucial to getting consistent and reliable printing outcomes.

Best practices for fabric selection based on texture.

Fabric selection based on texture is critical in order to achieve the desired printing effect in screen printing. Some best practices to be observed when fabric selection is based on texture are mentioned below:

- Consider the Design: Evaluate the intricacy and design details of the artwork to determine the type of texture that will complement the print. Intricate patterns and fine lines are optimal for smooth textures, while textured fabrics can increase the visual effect of simple designs by providing depth.

- Printing Technique: Consider what printing process is being used because different textures would react in various ways to various printing processes. Some textures may enhance or detract from some of the effects of printing, such as halftones or gradient. Choose a fabric texture appropriate to the desired printing process.

- Fabric Composition: Take note of the content of the fabric because it has the potential to influence the texture and printing outcome. Cotton and linen, natural fibers, will usually be soft in texture, while synthetic fabric like polyester and nylon will be more smooth or textured in quality. Every content of the fabric will yield unique textural features that will impact the final print.

- End Use: Consider the end use of the printed product when selecting fabric based on texture. Smooth-textured fabrics are normally used for apparel and products in direct contact with the skin because they are comfortable. Textured fabrics may be applied to decor items or designs meant to impart a sense of touch.

- Color Intensity: The texture of the fabric may also affect how colors appear on the fabric. Smooth fabrics will show colors more intensely and uniformly, while textured fabrics may produce a more muted or mottled effect. Choose a texture for the fabric that will enhance the color intensity and visual impact of the print.

- Testing and Sampling: Test and sample different textures of fabrics before starting a high-volume printing job to know the performance of each texture in relation to the ink and how they affect the final print outcome. You can make accurate decisions and adjust accordingly after you evaluate the test.

- Client Preferences: Consider your client or target market’s preferences in choosing fabric based on texture. There are some clients who have a liking for a specific texture because of its visual or feel aspects, so choosing fabric in accord with their preferences will direct your process of selecting fabric based on texture.

- Consult with Suppliers: Talk to fabric suppliers or industry specialists to get an idea about the properties and suitability of various textures of fabrics for screen printing. Suppliers can make suggestions based on their expertise regarding fabric properties and performance.

Absorbency :

Significance of fabric absorbency for screen printing

Absorbency of fabric is of great concern in screen printing since it has a direct effect on the quality, consistency, and shelf life of the printed design. Below are some of the most critical reasons why absorbency of fabric matters in screen printing:

- Ink Saturation: The absorbency of the material will influence how well the material can absorb the ink during the process of printing. A material with high absorbency will have the ink seep and penetrate into the fibers effectively, creating vibrant and long-lasting prints with rich colors and sharp details. Effective saturation of the ink is important in producing a high-quality and visually appealing print.

- Print Clarity: The absorbency of the fabric influences the print clarity and definition. A fabric with ideal absorbency enables uniform and even penetration of the ink, which results in distinct and clear prints. However, a low-absorbency fabric can produce uneven or mottled prints with irregular color coverage.

- Preventing Bleeding and Smudging: Fabric absorbency also prevents smudging and bleeding of ink during printing. The absorbent fabric picks up the ink instantly, keeping it from spreading or smudging beyond the designed limits. This is important to preserve the accuracy and integrity of the printed image.

- Color Fastness: The good absorbency of the fabric contributes to the color fastness of the print. If the fabric absorbs the ink nicely and holds the pigments, the print colors remain bright and not prone to fading even after repeated washing or exposure to outside conditions like sunlight and humidity. This ensures that the print remains visually appealing over time.

- Consistent Results: Fabric absorbency leads to consistent printing results on repeated batches and prints. If the fabric properly absorbs the ink, it ensures that each print carries the same level of intensity of color, detail, and clarity. Consistent absorbency leads to consistent print quality, which is required for professional and reliable screen printing.

- Drying Time: Drying time of the printed image is influenced by fabric absorbency. An absorbent fabric results in the quick absorption of ink, which translates to quicker drying and curing of the print. Printing efficiency and preparing the prints for further processing or handling is guaranteed with this.

- Compatibility with Inks: Various inks can have different requirements for the level of fabric absorbency to perform optimally. Knowing the absorbency of the fabric enables screen printers to choose the appropriate type of ink that works well with the fabric, leading to good-quality prints that stick well and display the desired properties.

How to choose fabrics with the best absorbency for optimal results

When selecting fabrics with the best absorbency for optimal results in screen printing, certain key considerations should guide your choice. Knowledge of the characteristics of different types of fabrics, including natural fibers like cotton and synthetic fibers like polyester, is essential. Testing the fabric samples to find the levels of absorbency, the spread of the ink, and color retention will determine the most suitable fabrics for your printing needs. Take into consideration the specific printing technique and ink to be utilized, as these may require fabrics with various absorbency levels for the best results. Seeking advice from fabric suppliers and taking into account the end-use of the printed material are also significant steps in choosing the correct absorbency level fabrics. By balancing factors such as fabric quality, testing, printing process, supplier recommendation, end-use, and ink compatibility, you can make fabric decisions that optimize absorbency to achieve high-quality, even, and visually appealing prints on your screen prints.

Color Vibrancy :

Effect of fabric type on color vibrancy and print quality

Fabric type has a huge impact on color vibrancy and print quality in screen printing. Various types of fabrics, for example, natural fibers like cotton and synthetic fibers like polyester, respond differently to ink, influencing the final look of the printed design. Natural fibers absorb greater amounts of ink, yielding intense and richly colored images with a soft, textured look. However, such absorbency has the effect of making colors subtly less intense compared to those which are printed using synthetic fibers. Synthetic fibers like polyester, for example, create excellent color intensity due to the smooth nature of their surface as well as the ability to hold pigments quite well. Polyester materials are known to exhibit vivid, saturated colors with clear details and even finish. Fabric type plays a crucial role in determining the overall color vibrancy effect and durability of the print and therefore needs to be selected based on the most appropriate fabric for achieving maximum color vibrancy and print quality in screen prints.

Regulations for the selection of fabrics that maximize color vibrancy

If you would like to enhance color vibrancy in screen printing, the selection of fabric is the most important factor. These are some guidelines for choosing fabrics that will assist in enhancing color vibrancy efficiently:

- Fabric Composition: Choose fabrics whose composition will support absorption and color retention. Natural fibers like cotton and linen, and synthetic fiber like polyester, which has a glossy texture, also help preserve colors well because of their capacity to retain the pigments that pass through and of their resultant look.

- Smooth Surface: A smooth-surface fabric is likely to reflect light more evenly and thus present colors in a more vibrant way. Smooth fabrics such as polyester or synthetics with a high synthetic content can make colors look brighter and more saturated than those that are textured.

- White or Light Colors: Light-colored or white materials make excellent bases in creating vibrant colors in screen printing. Light background colors enhance color visibility and vibrancy, so they are excellent for creating prints with color vivacity.

- Preferential Ink Absorption: Choose material with uniform absorbency of the ink and intense pigment holding potential. Highly absorbing materials have the ability to let colors penetrate further into fibers, which makes for more saturated color and less discoloration over time.

- Consider Fabric Weight: The lighter the fabric weight, the brighter and more vivid prints can be produced. Lighter weights have more freedom to absorb the ink, making it penetrate further into the material, creating greater color vibrancy and a nicer-looking print.

- Test Prints: To find out how a big print project will act on different fabrics before you begin, print tests on different swatches of fabric to gauge how each type of fabric reacts to the ink and impacts color vibrancy. The test print might identify fabrics that bring out maximum color vibrancy and achieve desired visual effects.

- Consult with Suppliers: Consult with fabric suppliers or industry experts to know what fabrics are most suitable for enhancing color vibrancy in screen printing. Suppliers know the properties of fabrics and how they perform, and they can advise you accordingly on what to use.

By considering factors such as the composition of fabric, texture of the surface, color, ink absorbency, weight of fabric, and running test prints, you can choose fabrics that create better color vibrancy and enable you to produce vibrant, attractive prints in your screen prints. The choice of appropriate fabric plays a fundamental function in enhancing color vibrancy and enabling you to attain the overall quality and impact of your printed pieces.

In selecting the screen printing fabric, consider the desired finish and feel of the finished product along with the type of design to be

FAQ: What fabric is used for screen printing?

Why is cotton a popular choice for screen printing?

Cotton is used because of its soft texture, effective water absorbency, and capacity to hold the ink, giving a nice appearance with a natural touch.

How is polyester cloth different from cotton for screen printing?

Polyester cloths yield a smoother fabric that allows wonderful color brightness and durability in screen printing. Polyester cloths are generally used because of their resistance to wrinkles and ability to repel moisture.

Are there specific fabric blends that work well for screen printing?

Cotton-poly blends utilize the strengths of both fibers and offer a balance of absorbency, color depth, and toughness for screen printing applications.

Is linen or nylon fabric ideal for screen printing?

Yes, textiles like linen, nylon, and other blends of natural and man-made fibers may also be screen printed, subject to the specifications of the quality of the ultimate print.

Should I conduct tests on fabric samples before starting a screen printing project?

Yes, testing fabric samples using your selected ink and printing process can enable you to ascertain the way different types of fabric respond to the ink and obtain optimum results in the ultimate prints.