DTF print is an innovative garment print technique offering high-quality, durable, and colorful prints on various fabrics. As a business owner, a fashion enthusiast, or someone who wants to advance printing practices, understanding what DTF print entails and how the process works can help you make the proper decisions.

This is a tutorial on DTF printing technology, printing process, materials needed, and why it is better compared to other techniques such as sublimation and screen printing.

Table of Contents

What is DTF Printing?

Direct-To-Film (DTF) printing is a digital printing process where the design is printed onto a special film and then transferred onto the substrate or garment using a heat press. DTF printing is a combination of the strengths of direct-to-garment (DTG) printing and heat transfer printing and is hence an effective and convenient way of producing full-color and detailed prints on fabrics and other substrates.

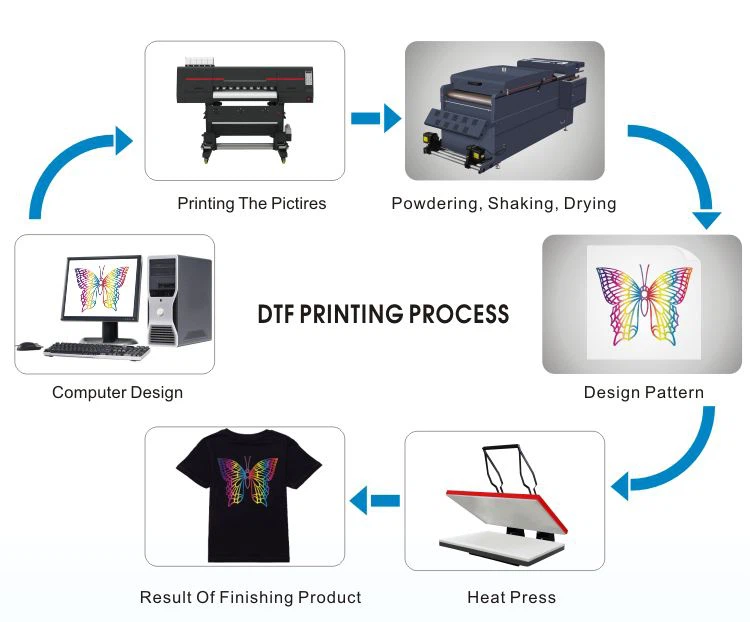

How Does DTF Printing Work?

- Design Preparation: The design is prepared digitally and printed on a specialized DTF film with a DTF printer that uses special UV-curable inks.

- Film Printing: The design is printed reversed onto the DTF film that is coated on one side with a water-soluble adhesive layer, which will adhere to the garment in the transfer process.

- Film Transfer: The printed DTF film is placed over the garment with the design facing downwards. The heat press is used to apply pressure and heat on the film to transfer the design onto the garment.

- Peeling Process: Once the transfer process is done, the garment is allowed to cool, and the DTF film is peeled off, leaving the printed image on the fabric.

- Curing: The printed garments may require curing through a heat press or conveyor dryer, depending on the ink type, to fix the ink permanently.

Advantages of DTF Printing:

High Detail and Resolution: DTF prints provide high resolution and clear printing with good detail, which is ideal for prints that have detailed designs and photographic prints.

Full-Color Printing: DTF printing provides full-color printing with no extra cost for multi-color printing, which is convenient for design freedom.

Flexibility: DTF printing can be applied to a lot of materials such as cotton, polyester, blends, and even on hard substrates such as ceramics and wood.

Quick Turnaround: DTF printing is quicker to set up than conventional screen printing and therefore ideal for small-batch and on-demand orders.

Eco-Friendly: DTF printing uses eco-friendly water-based inks, having a smaller environmental impact compared to standard screen printing inks.

What You Need for DTF Printing

1. Printer & Ink

- A DTF-compatible printer (converted Epson or dedicated DTF printer)

- DTF-specific inks (CMYK + White for opacity)

2. PET Film

- Special DTF transfer films that hold the ink and adhesive powder effectively.

3. Adhesive Powder

- Essential for bonding the ink to the fabric during heat transfer.

4. Heat Press Machine

- Needed for transferring the design from the PET film onto fabric.

5. RIP Software

- Software like Acrorip or Cadlink is used to manage ink distribution and optimize print quality.

Step-by-Step Guide to DTF Printing

- Prepare Your Design – Use software to create and adjust your design.

- Print on PET Film – Load the DTF film into the printer and print in mirror mode.

- Apply Adhesive Powder – Evenly distribute the adhesive powder over the print.

- Cure the Powder – Heat the powder to ensure proper adhesion.

- Press Onto Fabric – Use a heat press at the recommended temperature and time.

- Cool & Peel – Let the fabric cool before peeling off the PET film for the final result.

Conclusion

DTF printing is a game-changer in the custom apparel world, offering high-quality, long-lasting, and vibrant prints on a variety of fabrics. With the right equipment, supplies, and techniques, you can create professional-quality prints without the expense. DTF printing is an excellent choice for long-lasting, high-resolution prints, whether starting a business or taking printing to the next level.