Understanding Salmon Skin Texture on 3D Prints: Causes and Solutions

3D printing has transformed everything from design to manufacturing, providing limitless possibilities to create sophisticated prototypes and functional parts. However, getting an excellent 3D print is hardly a cakewalk. “Salmon skin”, the most common dilemma faced by novices and experts alike during the printing process, is one.

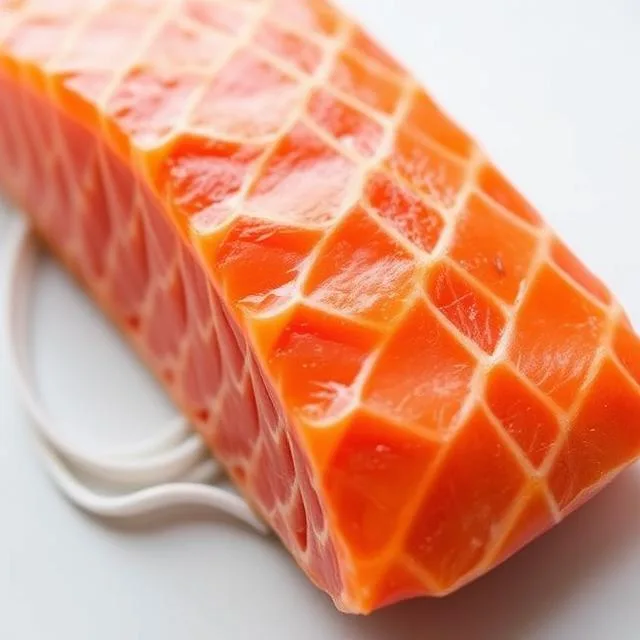

Salmon skin describes a fish-scaled finish that sometimes comes to being on the surface of prints. Though generally, this problem is not of great consequence to the pressing issue of print functionality, it indeed detracts aesthetically from the said project. Well, if your prints are suffering from this nuisance, you are not alone. This article will look at the factors behind salmon skin on your 3D prints and how you can rectify it to give a smooth, professional-looking finish.

Table of Contents

Exploring the Salmon Skin Texture:

Root Causes:

- Layer Height: Higher layer height supports show distinct layer lines and the salmon skin texture.

- Inconsistent Extrusion: Uneven extrusion rates or obstruction of filament flow during printing can lead to irregular patterns upon the printed object.

- Print Speed: Too much print speed may not give enough time for layer set up due to cooling, which may exaggerate the effect of salmon skin.

- Print Temperature: Wrong print temperature changes criteria for material flow and ultimately adhesion and impacts the surface quality.

What Causes Salmon Skin on 3D Prints? :

Salmon skin occurs due to a few problems or causes during the 3D printing operation, with temperature, extrusion, retraction settings, and cooling contributing to this defect in different ways. Let us look closely at some causes of salmon skin:

1. Inconsistent Extrusion :

The highest contributor to salmon skin is inconsistent extrusion. This occurs when the 3D printer’s extruder does not release filament uniformly. An irregular flow of material can form bumps or grooves on the surface of the print leading to the formation of the salmon skin texture.

- How to Fix:

- Calibrate the Extruder: Be sure your extruder is calibrated correctly for a consistent flow rate.

- Check the Filament: Use filament made from high-quality material that flows smoothly without clogs or having any inconsistencies.

2. Incorrect Retraction Settings :

Retraction, when performed properly, is the function of the printer whereby the filament is mildly pulled back when there are movements in-between printing areas to avoid oozing. Incorrect retraction settings (too much or insufficient) would lead to inconsistent extrusion, which translates directly into the appearance of salmon skin.

- How to Fix:

- Adjust Retraction Settings: Test various retraction distances and speeds until a setting leads to consistent extrusion, free from gaps or blobs on the print surface.

3. Overheating of the Print :

Very high temperature of the hotend burns the filament excessively, and the nozzle releases too much material in one go. This overheating leads to the rough surface texture of the prints.

- How to Fix:

- Set Optimal Print Temperatures: Your printer should work within the given temperature range for the filament, e.g., 190-220ºC for PLA, 230-250ºC for ABS.

- Avoid Excessive Heating: If he keeps insisting on being too hot, drop the print temperature a notch.

4. Poor Cooling of the Print :

Cooling influences the quality of 3D prints; hence, if cooling is too aggressive, the layers bond poorly, thereby being subjected to salmon skin and other surface blemishes. If cooling is too slow, the material will sag or warp.

- How to Fix:

- Use Cooling Fans: Enable or tune your print cooling fans in order to ensure balanced cooling for all layers.

- Fine-tune Cooling Settings: Gradually increase or decrease the cooling fan speeds for different materials and layer heights.

5. Uneven Layer Height :

If the layer height for any operation on the 3D printer is too large/unbalanced, the extruded material can lead over bumps, whereby the section will be marked with visible lines or surface texture defects. A variable layer height would often add to the “grainy” or bumpy feel that salmon skin is characterized with.

- How to Fix:

- Check Layer Height Settings: Smaller layer height settings 0.1-0.2mm result in better details and smoother finish.

- Calibrate the Z-Axis: Make sure your printer Z axis is correctly calibrated to provide even deposition at the layer settings being used.

6. Print Speed and Travel Movements :

An incorrect print speed can be very fast or very slow, which creates inconsistency in the behavior of extrusion and adds to the salmon skin. Similar to that, travel movements, that is the moves that the printer makes between printing areas, could also interfere with the consistency of filament deposition.

- How to Fix:

- Adjust Print Speed: Reduce your print speed for better control over extrusion and cooling.

- Optimize Travel Movements: Ensure your printer’s travel settings are optimized to minimize stringing or oozing during non-print moves.

How to Prevent Salmon Skin in 3D Printing :

Now that we know the causes, let’s discuss the prevention of salmon skin on the 3D prints.

1. Use the Right Filament :

Using the correct filament matters greatly when it comes to having smooth and consistent prints. High-quality filament with consistent diameter and very little amount of impurities will act to reduce the risk of salmon skin.

- Best Filament Types:

- PLA is a beginner-friendly filament that tends to produce smoother prints with less chance of surface defects.

- PETG is another excellent option that balances flexibility and durability without compromising surface quality.

2. Calibrate Your 3D Printer :

Calibration maybe often ignored but is an important aspect of keeping prints at court. Calibration puts the extruder, bed, and other axes in alignment with each other and helps to avoid extrusion inconsistencies and defects which lead to salmon skin.

- Steps to Calibrate:

- Calibrate the extruder to ensure consistent filament flow.

- Level the print bed for even adhesion.

- Fine-tune your Z-axis and layer height settings.

3. Optimize Your Print Settings :

Optimizing your print settings is paramount in stopping salmon skin effects. Start with tweaks on the retraction settings, speed of printing, and layer height, all meant to limit texture defects.

- Recommended Settings:

- Retraction Distance: 4-6mm (depends on the filament and printer).

- Print Speed: 40-60mm/s for better control over extrusion.

- Layer Height: 0.1-0.2mm for fine details.

4. Maintain Proper Cooling :

Proper cooling makes sure that layers stick together properly without any texture issue. Remember to operate the cooling fans during printing, especially while printing with materials like PLA.

5. Use a Heated Print Bed :

Heated print beds help prevent warping and keep the first few layers firmly anchored for minimizing surface defects.

Resolving Salmon Skin Effect with TL Smoother

Every 3D printing enthusiast or professional aims at achieving an impeccable sheen on their prints. But sometimes, these aspirations are dampened by the salmon skin effect that leaves behind unwanted textures and imperfections on printed items.

The best anti-salmon skin weapon is the use of a TL Smoother in your 3D printing setup. TL Smoothers are small modules aimed at enhancing the performance of stepper motor drivers to achieve smooth and precise head movements during printing.

With a TL Smoother, you can prevent the ghosting and ringing and, most importantly, the salmon skin effect. The module serves to filter electrical noise and dampen vibrations, which usually affect extrusion and layer deposition uniformity and, in the process, create a rampart against the smoothening of the surface of your prints.

The TL Smoother instruction is straightforward, and they do highly improve the quality of prints. This small upgrade gives a chance to bring its owner smoother prints with professional looks and fine surface finishing with no disrupting fish-like pattern caused by the salmon skin effect.

In summary, matching up your 3D prints to your expectations and getting rid of the salmon skin effect can be achieved with a TL Smoother on your 3D printing kit. For a small investment, one can really change the entire look and feel of the print, moving ever so close to the hollow dreams of perfection in 3D printing.

Conclusion:

By identifying the causes of salmon skin texture on 3D prints and implementing the suggested solutions and tips, enthusiasts could improve their prints quality and render them smooth and professionally done. The road toward perfection will mostly be paved with experimentation, tweaking, and a fine eye to detail in mitigating textural imperfections and enhancing the overall 3D printing experience.