Screen printing, also referred to as silk screening, is a widely used and popular print process that uses a mesh screen to transfer ink onto a substrate. The technique is utilized in the creation of high-quality prints on different substrates such as textiles, paper, glass, metal, and plastic. Screen printing enables bold colors, exact details, and longevity and hence is the optimal technique for making prints with graphic designs and intricate patterns.

It is the method of forming a stencil on a mesh screen, which acts as a barrier to the ink except where the design is intended to be printed. The ink is then forced through the screen using a squeegee, duplicating the design on the substrate below. Screen printing is versatile in terms of the substrate and ink type that can be utilized, making it possible to customize and be creative in the printing. Regardless of whether it is being utilized to make custom clothing, posters, signs, or promotional products, screen printing is still a versatile and practical technique for producing high-quality prints with durable results.

Table of Contents

Here is an overview of how screen printing works, its benefits, and common applications:

How does screen printing work?

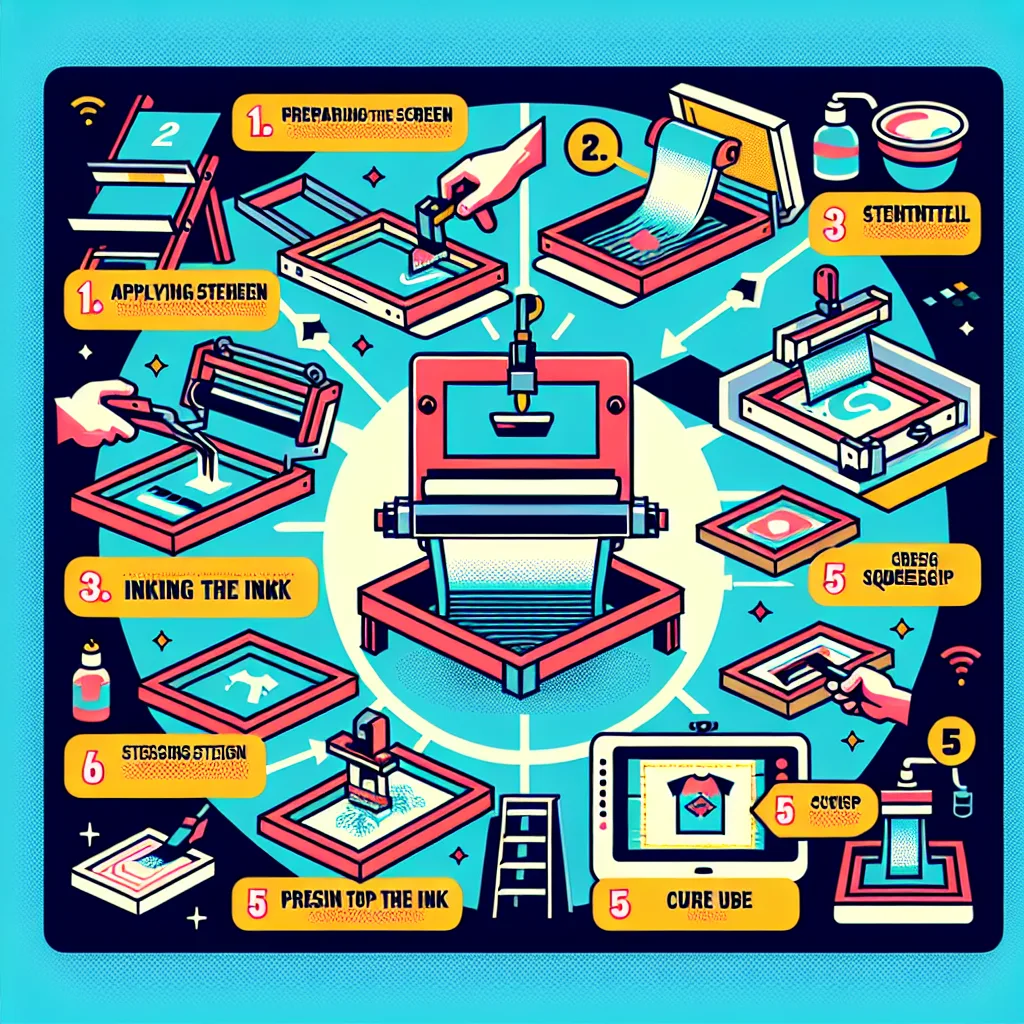

Screen printing involves several techniques, all based on the same principle. One of the most prevalent forms of screen printing involves using a light-reactive emulsion to produce bespoke stencils, a process immensely popular in professional settings for its ability to craft intricate designs with precision. In the following step-by-step breakdown of the process of screen printing, we delve into the intricacies of the process. To provide you with the complete picture, we’ve supplemented our description with a video that shows you the process in action in our workshop, providing you with a firsthand view of the way our meticulously produced custom screen-printed apparel is created.

- Design Preparation: It begins with preparing a design which is digitalized and separated into single color layers to be printed.

- Screen Preparation:A good screen preparation is necessary to achieve good results in screen printing. To get a better screen to print with, begin with a fine mesh screen that will be appropriate for the detail in your design. Stretch the screen tightly to facilitate smooth ink transfer and sharp prints. Coat the screen with a good emulsion in a dark room and expose it to UV light using a film positive of your design to get a sharp stencil. Wash out the unexposed emulsion to reveal the stencil. When the screen is ready, position it correctly on the print surface and clamp it firmly in place. A good-quality squeegee and the right type of ink for your substrate will also give the best results. Regularly inspect and look after your screens to provide durability and consistency of print. If you follow these vital steps and use good quality material, you will be able to create a better screen for screen printing that can give you professional and long-term prints.

- Ink Application: Ink is poured over the screen on top of the stencil. A squeegee pulls the ink over the screen, pushing it through the stencil and onto the substrate.

- Printing Process: The substrate is positioned under the screen, and the ink is pushed through the stencil onto the substrate. Additional layers of color are printed separately, in accurate registration to create a full-color image.

- Curing: Curing is an important step in the printing process that helps in attaining durability and long lifespan of printed materials. Curing is the application of heat, light, or chemicals to the printed ink in order to harden and bond well to the substrate. It is a critical process in many types of printing, including screen printing and digital printing, since it transforms the liquid ink into a hard, permanent finish. In screen printing, for example, curing generally means running the printed material through a conveyor dryer or heating the ink to heat-set it in a heat press. For digital print methods such as UV printing, UV light is generally used to cure the ink immediately after it is printed. Proper curing not only strengthens the adhesion of the ink to the substrate but also makes the print resistant to fading, scratching, and other types of wear and tear, ultimately leading to a high-quality and durable printed product.

Five Advantages of Screen Printing:

- Versatility: The much-loved screen printing is possibly one of the most versatile printing methods of them all. Just consider the sheer array of materials-such as fabric, paper, plastics, metal, glass, and even more-that can be printed on, allowing for the most diverse and creative output of screen printing. Of course, it is this adaptation that makes it suitable for items made in such different spheres as custom apparel, posters, signage, labels, and promotional products: items with vivid colors and intricate designs. The various types of inks, including specialty inks like metallic or glow-in-the-dark, make it even more exciting for designers and artists in the creative process. Screen printing is versatile in terms of its scalability, meaning it can work well for custom smaller projects and large production runs as well as other ways. In addition, the durability and longevity of screen-printed products contribute very much to making cost-efficient businesses and individuals searching for high-quality, long-lasting prints. All in all, versatility in screen printing unlocks the power in the creator to bring visions to life over a multitude of surfaces with amazing detail and vibrant color.

- Durability: Probably the best definition of a durable print is a screen-printed image that stands up very well to washing.

- Vibrant Colors: Screen printing is one of the techniques that allows the accuracy of production at its best in conditions that provide the opportunity to easily get bright and striking colors, making this method the most popular among those who create visually appealing prints. With multiple layers of inks used, the screen printing allows you to set up that color richness and saturation depending upon the substrate. By layering different colors of ink on top of each other, screen printers can create a wide spectrum of shades and tones, achieving intricate color blends and gradients with ease. When inquiring about specialty inks such as metallics and fluorescents, it adds to the array of colors available for screen printing inks and can further enhance the richness of the final prints itself. This opacity and thickness of the ink in the screen printing probably contribute a lot to the richness and intensity of colors, putting designs into the range of very audible visual perception. With this way of getting vibrant colors very precisely and consistently, whether for textiles, paper, or anything else, screen printing has the best advantage over other methods in terms of achieving very bright and strong visuals.

- Cost-Effective for Bulk Orders: Probably among the biggest advantages offered by screen printing is the capability to print it faster than other processes and at lesser costs when producing large quantities. Screen printing is one method preferred for mass reproduction as harnessed by this set-up procedure, i.e. preparing the screens. Economies of scale, per unit cost decrease proportionately in volume; and even units add up to cost-effective printing, particularly for designs with few colors, because the upfront costs are generally fixed, so color use may be of little consequence. Thus, creating variable ranges for the amounts used in custom apparel, promotional items, event merchandise, and even more does not compromise quality per volume.

- Special Effects: With screen printing, it is easy to achieve unique foil printing, puff printing, or high-density printing.

What are the applications of screen printing?

- Apparel: One of the major applications of screen printing in the apparel industry is giving it value as a versatile and cost-effective way of producing an individual’s custom-designed clothing. Whether designing t-shirts, hoodies, caps, or jerseys, screen printing allows for bright and long-lasting prints on all different types of apparel. It is also admired by many people when it comes to the production of formats for their fabrics since its method allows them to achieve high-quality, longer-lasting results while still being detailed and bright in colors. Whether print designs are made up of intricate graphics, logos, slogans, or personal images, this approach could be the best way to go since it can meet the different stylistic specifications of individual customers, sports teams, businesses, or organizations. Also, with various fabric types, whether it is cotton, polyester, or blends, this method gives prints that remain vibrant for many wash cycles. Perfect for all kinds of personal style choices above all because of versatility and even durability-plus a site-blazing spot of designs, screen printing remains popular in apparel decoration as it opens up to infinite design possibilities for creating custom and stylish clothing pieces.

- Signage and Posters: For large format print production of eye-catching posters, banners, signs, and displays, screen printing is an indispensable tool. Touted as a highly versatile printing method, screen printing excels above all others in producing propelling and colorful designs on paper, vinyl, textile, etc., thereby making it best suited for large-scale visual communication processes. From advertising to promotional events and trade shows to decoration, attention-grabbing graphics with sharp details and intense colors can be created using the screen printing method. The great durability of these screen-printed materials means that large-format prints can withstand the elements outside and endure heavy use throughout their life, making them suitable for any environment, especially outdoors indoors. Using the incredible impact and scalable nature of screen printing, firms, organizations, and individuals alike will convey their messages and grab attention through stunning visuals on posters, banners, signs, and displays.

- Promotional Products: Screen printing is, quite simply, the best method to brand and deliver marketing messages on a wide range of goods such as bags, drinkware, and accessories. This printing technique lets companies brand their products with appealing logos, slogans, and other promotional material that now stands up to multiple washes and use. Whether that be a logo on a tote bag, an eye-catching slogan on a water bottle, or any brand message on such varied items as hats or phone cases, screen printing is a cost-effective and qualitative solution towards personalizing items in mass. Its versatility along with the vibrant colors of screen-printing ink means the branding or marketing messages are bound to stand up and make an impression on customers. By screen-printing onto bags, drinkware, and accessories, companies returning the favor of fundamentally keeping track of the target audience with branding and rememberable promotional products to make an everlasting impression.

- Fine Art: Screen printing permits an artist to create limited series prints, one-off works, or composed illustrations. Adjustment work entails precision and consistency in replicating original artwork, with the actual production of several copies of a given design while maintaining the quality and integrity of the original work. In such cases, screen printing offers vast opportunities for an artist to play with color, texture, and layering techniques, leading to breathtaking looks that bring their vision to fruition. Fine details and subtle patterns can also be reproduced with acuity, making screen printing one of the better ways to transpose complex artwork upon paper, canvas, and fabric alike. To collectors and art lovers, limited edition screen prints hold their charm as they give one a way of possessing something truly different and unique at the same time. Through screen printing, the artist can create for a wider audience, express the fullness of their creativity, and fabricate images that enthrall both the viewers and art lovers.

- Industrial Applications: The screen printing process covers a very important role in industries such as electronics, automotive, etc., where it allows for the printing of designs, labels, and markings on parts, panels, and components. As applied within the electronics industry, screen printing is typically utilized for circuit board printing, application of conductive inks, and accurate labeling of electronic components. By customizing and identifying different parts, screen printing facilitates assembly and quality control. In the automotive industry, screen printing is also used for marking parts, panels, and components with relevant information, including serial numbers, logos, and safety warnings. The durability and versatility of screen printing make it an ideal technique for insuring that the markings withstand harsh environmental conditions and remain legible over time. It is an efficient and reliable technique that screen printing promotes for enabling various industries to apply design and information onto all kinds of materials. It contributes to the functional branding and identification of parts and components that are vital for the manufacturing and assembly processes.

In conclusion, screen printing makes an excellent means of making prints as it is elegant, creates highly durable impressions and applications across a variety of industries. Understanding the process and the benefits of screen printing can help businesses, artists, and individuals use this printing technique to their advantage for getting high-quality beautiful prints on different substrates.

FAQ : Frequently Asked Questions About Screen Printing

Will screen printing ink wash out?

If properly done in screen printing, heat-treated washable ink is what a trained professional uses; it is not supposed to “lavage” the print. To make the colorfastness, the printer needs to make sure that the ink is set according to the manufacturer’s guidelines. The correct drying temperature and the time may differ with the kind of ink and fabric used; the printer must carefully follow instructions if they want to create a long-lasting, washable item.

What about the environment and screen printing?

Of course, screen printing produces waste in the way of inks and chemicals; however, eco-friendly inks can be used, materials can be recycled, and environmental impacts can be minimized through proper disposal and recycling practices.

How long do screen prints last?

What you will find best known about screen printed materials is their fame for longevity. The prints, for example, last after many washes (in reference to textiles) as well as in terms of fading, thus providing a long-term option for various applications.

Can screen printing be done on dark-colored fabrics?

Yes, a color underbase can be achieved by screen printing on dark fabric when you use white ink to make the colors in the design look bright and solid on that dark background.

How can I start screen printing?

In your list of needs for screen printing is the right equipment: screens, inks, squeegees, and the printing surface. With that, you could then supplement that with a little tutorial learning or workshop/career sessions that would enable your skills to develop with this versatile printing method.