Acing the craftsmanship of priming and painting 3D printed parts could be a significant aptitude for achieving professional-looking comes about in your ventures. The method starts with fastidious arrangement, guaranteeing the surface is clean, smooth, and free of blemishes. Legitimate preparing is key; it makes a uniform base coat that improves paint attachment and wrap up toughness. Selecting the proper preliminary for the fabric utilized in printing is basic, whether it’s PLA, ABS, or other sorts of fiber. When it comes to portray, choosing high-quality acrylic or finish paints can make a critical contrast within the last appearance. Procedures like airbrushing or hand-painting offer diverse levels of exactness and wrap up. Layering paints, mixing colors, and including detail work can raise the aesthetics of your 3D printed parts. At last, a clear coat or varnish gives assurance and a cleaned see. By taking after these steps fastidiously and testing with distinctive strategies, you’ll be able change your 3D printed manifestations into professional-grade pieces that stand out for their quality and visual request. Here’s a nitty gritty direct on how to prime 3D printed parts viably:

Table of Contents

Steps to Prime 3D Printed Parts:

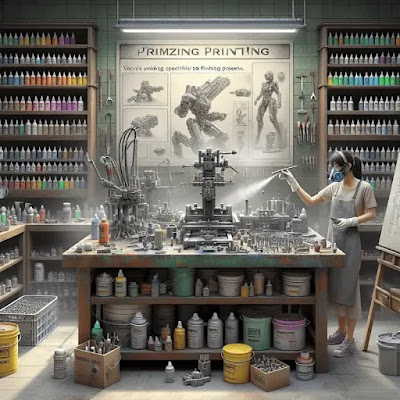

Prepare the Work Area:

Set up a well-ventilated and dust-free workspace for preparing your 3D printed parts. Guarantee appropriate ventilation to scatter exhaust from the preliminary.

Clean the 3D Printed Part:

Altogether clean the 3D printed parts utilizing isopropyl liquor or a gentle cleanser arrangement to expel any tidy, flotsam and jetsam, or buildup from the printing prepare. Permit the portion to dry totally some time recently priming.

Select a Primer:

Select a reasonable groundwork based on the fabric of your 3D printed part and the sort of wrap up you crave. Preliminaries outlined for plastics or particularly for 3D printing are suggested for best comes about.

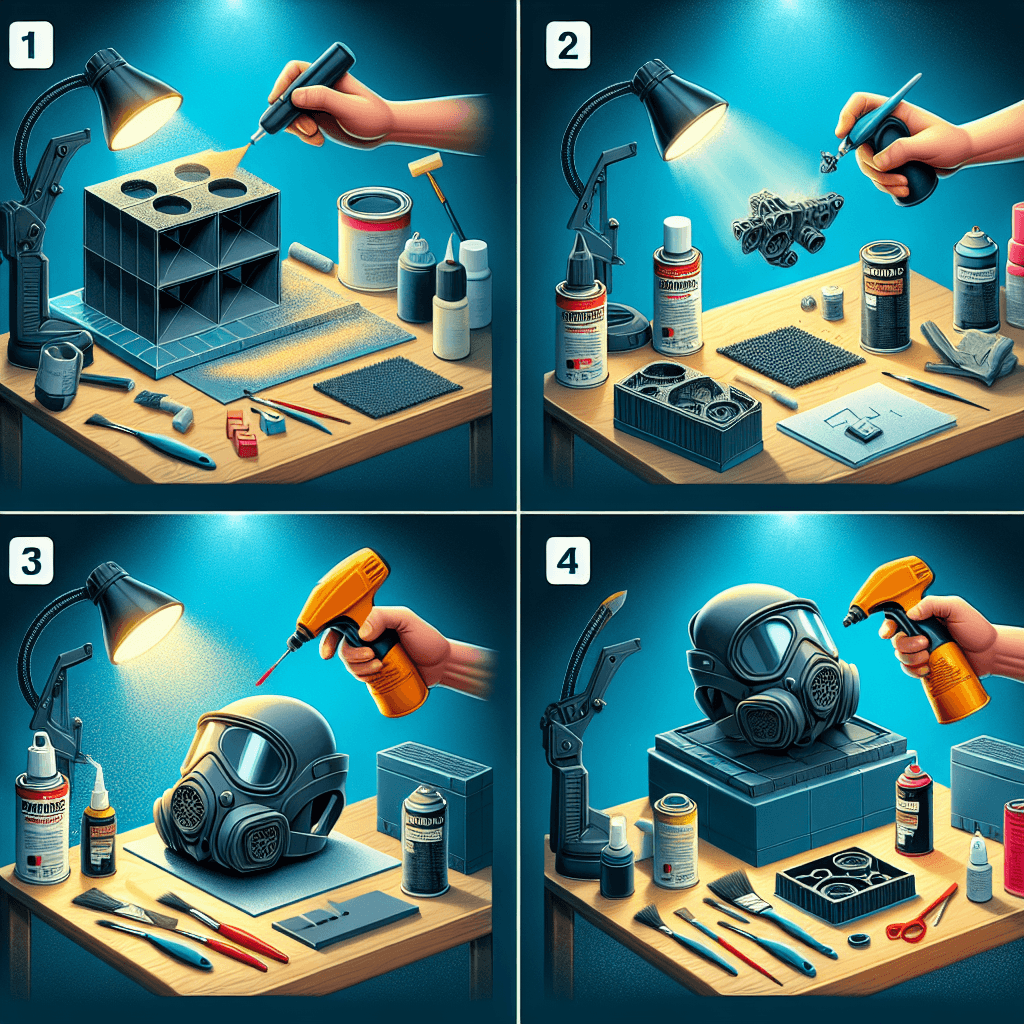

Apply the Primer:

Shake the preliminary canister well to guarantee legitimate blending of the item. Hold the canister approximately 6-8 inches absent from the portion and shower a light, indeed coat of groundwork over the complete surface. Dodge applying the preliminary as well thickly to anticipate dribbles or pooling.

Allow Drying Time:

Take after the manufacturer’s enlightening for the drying time of the groundwork. Ordinarily, preliminaries require 15-30 minutes to dry to the touch and a few hours for full curing. Guarantee the portion is completely dry some time recently continuing with advance wrapping up steps.

Inspect for Imperfections:

After the groundwork has dried, review the 3D printed part for any blemishes, such as uneven scope, harsh spots, or dribbles. Sand down any harsh zones tenderly with fine-grit sandpaper some time recently applying extra coats of preliminary in the event that required.

Apply Additional Coats (Optional):

Depending on the specified wrap up and smoothness of the part, you’ll select to apply numerous coats of primer. Permit each coat to dry totally some time recently applying the another one, and softly sand between coats for a smoother wrap up.

Finish the Primed Part:

Once the ultimate coat of primer has dried and cured, you’ll continue with painting, sanding, or applying other wrapping up strategies to accomplish the required hunt for your 3D printed part.

Protective Measures:

Wear suitable individual protective gear, such as a respirator or cover and gloves, when working with primers to secure yourself from exhaust and chemicals.

Clean Up:

Delete exactly all primer and cleaning materials used depending on the local regulations to remove hazardous waste.

Conclusion:

Priming 3D printing parts is an important step to prepare them for painting or other finishing processes. By following these steps and using the right primer and appropriate techniques, you can get a smooth and professional surface on your 3D printing parts and improve the overall quality of impressions. .

The purpose of using primer for 3d prints

the use of primer for 3D prints to serve some important ending in the process of finishing, eventually improving the overall appearance and quality of the printed parts. Here are the main reasons why the use of primer is beneficial for 3D printing:

Purpose of Using Primer for 3D Prints:

Surface Preparation: Primer helps prepare the surface of 3D printed parts by filling in small defects, gaps, and layer lines that are often present in the printed object. The result is a smoother and more even surface for the next end.

Improves Adhesion: Primer promotes better adhesion of the following paint layers or other finishing materials on the surface of the 3D printed part. It creates an appropriate basis for the picture to comply, preventing the coat or scales of the finishing layer.

Enhances Paint Finish: Apply primer before improving the overall ending of the printing part by providing a coherent basis. It helps paint to dry evenly and reduce the number of layers needed to achieve vibrant and uniform colors.

Fills Gaps and Defects: Check the start to fill the gaps, gaps and small layers on the 3D printed surface, creating a more shiny appearance. It smoothes rough areas and imperfections, leading to a more professional product.

Seals and Protects: benefits are a protective layer, sealing the surface of 3D printing part and providing a barrier against moisture, dirt and other environmental factors that can damage printing by printing time.

Easier Sanding and Finishing: Primed surfaces are ground with sanding 3D printing to make them easier to work with. The smooth surface produced by the primers allows for more precise finishing techniques such as sanding and polishing.

Uniform Color and Texture: Primers create a uniform foundation for your paint and ensure that the final finishing colors and textures are consistent across the printed parts. It also helps prevent the underlying color of the filament from showing the color paint.

Professional Appearance: primers, 3D printed parts can achieve a more professional and refined appearance, making them suitable for display, presentation, or functional use in various applications.

Conclusion:

In summary, the use of primers in 3D printing improves surface quality, improves paint and other surface responsibility, and fills in gaps and imperfections, and allows for parts and experts to be used. It is essentially important to protect it. To achieve the appearance. Inclusion of primers in the finishing process can enhance the general quality and aesthetic appeal of 3D printed parts. This makes it more visually appealing and durable for many applications.

How many coats of primer on a 3D print?

The number of primer coats that can be applied to 3D printing will vary depending on the desired finish, print surface condition, primer used, and personal preference. Some general guidelines for determining the number of primer coats in 3D printing are as follows:

Factors that affect the Number of Primer Coats:

Surface Condition: 3D printing part have visible layer lining or possibly defects, apply multiple coats primers to achieve smooth, uniform surfaces .

Desired Finish: The conclusion you want to reach also determines the number of primer coats. For perfect and professional surfaces, several primer layers should be used to ensure a smooth foundation for painting and other finishing techniques.

Material and Color of the Print: 3D printing materials and filament colors can affect the primer cover. Darker prints may require additional layers to achieve full coverage compared to light-colored prints.

Guidelines for Applying Primer Coats:

Initial Coat: Start with a single light primer layer to create the first base layer. This coat helps the next layer stick better to the print surface

Assess the Coverage: After drying the first layer, evaluate the cover and smoothness of the surface. If the defect is still visible, you should use additional coats if necessary.

Additional Coats: additional primer layers to achieve the desired level of smoothness and cover. Usually, 2-3 primer layers are sufficient for most 3D printing.

Sand Between Coats: Fine grain sand between each primer layer will slightly smoothen the surface, ensuring a uniform finish.

Final Inspection: After using the required number of primer coat, inspect the surface of the 3D printing for remaining defects. Place it as needed before continuing with the painting or any other final steps.

Finish with Topcoat: After the final layer of primer has dried and healed, continue to apply the top coat color or other finishing material to achieve the desired color and finish of the 3D printing parts.

Conclusion:

The number of primer layers applied to 3D printing depends on a variety of factors such as surface condition, primer type, desired finish, material/pressure material/color, etc. By evaluating the surface and applying multiple layers as needed to ensure a smooth and uniform base, you can improve the overall quality and appearance of your 3D printed parts to a professional finish.

What type of primer to use on 3d prints figures?

When choosing primers for 3D printed figures, it is important to select primers specifically formulated for the use of plastics, including the type of material made up of 3D printing (PLA, ABS, PETG, etc.). . Here are some recommendations regarding primer types for 3D printing:

Types of Primers for 3D Printed Figures:

Acrylic-based Primer:

Acrylic Primers are versatile and are usually used to priming 3D printed figures. They provide excellent liability and compensation for a variety of materials, including PLA and ABS.

Adhesion Promoting Primer:

Adhesive Promotion Primers are designed to improve binding between the primer and the surface of 3D printing. These primers are especially useful to ensure lacquer adhesion of 3D printed figures.

Sanding Primer Filler:

Sanding Primer Filler 3D Print surfaces create a smooth foundation for painting. These primers can be sanded for a perfect finish.

Plastic-specific Primer:

Primers specifically formulated for plastic surfaces are ideal for 3D printed figures made from materials like PLA, ABS, or PETG. These primers are responsible for the plastic and provide a permanent foundation for painting.

Spray-on Primer:

Spray-on Primer is comfortable to cover a wide area quickly and evenly. Find spray readers designed for plastic surfaces and prepare simple applications for 3D printing.

Automotive Primer:

Automobile Primers are known for their durability and strong adhesion properties. They are suitable for priming 3D printed figures that may require additional protection or smooth finish.

Primer for Specific Materials:

Specially formulated for certain materials such as ABS and PLA. These primers are tailored appropriately to the unique properties of each material and are recommended for optimal results.

Tips for Choosing and Using Primer:

- Test on a Small Area: Primers in small modest areas to ensure compatibility and responsibility with the material of printing before priming the entire part.

- Follow Instructions: always follow the manufacturer’s instructions for specific primer, including drying times, application techniques, and safety precautions.

- Ventilation: Use primers in a well-ventilated area or wear a respirator mask to avoid inhaling fumes. Follow the security guidelines provided by the primer manufacturer.

- Sand Between Coats: For smooth finish, sand the primed surfaces between layers to remove all defects and ensure uniform coverage.

By selecting the appropriate type of primer designed for plastic surfaces and following best practices for application, 3D printed figures can achieve a smooth and durable foundation for painting and finishing with professional results.

Best Primer to Use for 3D Prints?

When choosing the best primer for 3D printing, it is important to choose a product that offers excellent quality, smooth covering and compatibility with the specific material of 3D printing. Popular and widely recommended primers for 3D printing:

Best Primers for 3D Prints:

Rust-Oleum Painter’s Touch Ultra Cover Primer:

This acrylic-based primer works well on various materials, including plastics commonly used in 3D printing. It offers excellent adhesion and smooth cover making it a popular choice for priming 3D prints.

Krylon Fusion for Plastic Primer:

Specifically formulated for plastics, Krylon Fusion for Plastic Primeris designed in a combination method of plastic surfaces containing 3D printing. Provides outstanding adhesion and durability for your painting projects.

Rust-Oleum Automotive Primer:

Rost-Oleum Automotive Primer is known for its durability and adhesive properties. Suitable for priming 3D prints and requires additional protection or smooth finish. such as Automotive parts or functional prints.

Dupli-Color Adhesion Promoter:

Dupli-Color Adhesion Promoter is an excellent choice for enhancing paint adhesion on 3D printed figures. It creates a strong bond between the primer and the surface of the print, helping to ensure long-term results.

Rust-Oleum Sandable Primer:

Rust-Oleum Sandable Primer Filler is perfect for filling out defects and layers on surfaces of 3D printing. It can be sanded down to achieve a smooth and flawless finish before painting.

Tamiya Fine Surface Primer:

Tamiya Fine Surface Primer is a popular choice among hobbyists and model makers for priming plastic models and 3D prints. It provides a smooth base for adhering to paintings and various materials.

Rust-Oleum Universal Bonding Primer:

Rust-Oleum Universal Bonding Primer is designed to bond to a wide range of surfaces, including plastics. It provides good adhesion and coverage, making it suitable for priming 3D prints before painting.

Considerations When Choosing a Primer:

- Material Compatibility: make sure your primer is compatible with 3D printed materials such as PLA, ABS, PETG, etc.

- Application Method: Choose a primer that suits your preferred application method, such as

- spray, brush, or airbrush.

- Drying Time: Look at the drying time of the

- primer. Especially when you need to apply multiple layers or tackle complex details.

- Finish: Depending on the desired finish (e.g., matte, satin, glossy), select a primer that complements the final look you want to reach.

By selecting a high-quality primer that is compatible with your 3D prints and meets your specific requirements, you can ensure a smooth and professional look finish for your projects.

Step by Step: Painting 3D Printed Parts

Painting 3D printed parts are a great way to enhance their appearance and give your project a personal touch. Here are step-by-step instructions for effective painting of 3D printed parts :

Step-by-Step Guide to Painting 3D Printed Parts:

Prepare the Work Area:

Set up a well-ventilated and dust-free workspace with a protective covering to prevent paint from getting on surfaces you don’t want to be painted.

Clean the 3D Printed Part:

Thoroughly clean the 3D printed part with isopropyl alcohol or a mild detergent solution to remove any dust, oils, or residues. Allow the part to dry completely before painting.

Apply Primer:

Apply a suitable primer to the clean and dry 3D printed part. Choose a primer specifically formulated for plastics and follow the manufacturer’s instructions for application. Allow the primer to dry completely.

Sand the Primed Surface (Optional):

If needed, lightly sand the primed surface with fine-grit sandpaper to smooth out any imperfections and ensure a uniform base for painting. Wipe away any dust with a clean, dry cloth.

Select Paint and Colors:

Choose high-quality acrylic or enamel paints suitable for the material of your 3D print. Select the colors you want to use for your project and ensure they are compatible with the primer and each other.

Apply the Base Coat:

Start by applying a base coat of paint to the 3D printed part. Use thin, even strokes to achieve a smooth and consistent coverage. Allow the base coat to dry completely before applying additional coats.

Add Details and Layers:

Use smaller brushes or detailing tools to add intricate details or multiple layers of paint to create depth and dimension in your design. Allow each layer to dry before adding the next.

Allow for Drying Time:

Patience is key when painting 3D printed parts. Allow each coat of paint to dry thoroughly before applying the next layer. This helps prevent smudging or mixing of colors.

Apply Topcoat or Sealant (Optional):

Once you are satisfied with the paint job, consider applying a clear topcoat or sealant to protect the finish and add durability to the painted surface. Follow the manufacturer’s instructions for application and drying times.

Inspect and Touch Up:

After the paint has fully dried, inspect the 3D printed part for any imperfections or areas that may need touching up. Make any necessary corrections with additional paint or detailing.

Display or Use:

Once the paint has dried and any touch-ups are complete, your painted 3D printed part is ready for display or use in your projects. Handle with care to preserve the finish.

Conclusion:

By following these step-by-step instructions and using high-quality materials, you can achieve a professional and visually appealing paint finish on your 3D printed parts. Try out a variety of colors, techniques and surfaces to create unique and personalized designs that show your creativity and attention to detail.

What is the best paint for 3D printed parts?

When selecting paint for 3D printed parts, it’s important to choose a type of paint that adheres well to the material of the print, provides a good cover and a permanent finish. Below are some of the best types of paint that are normally used to paint 3D printing parts:

Best Types of Paint for 3D Printed Parts:

Acrylic Paint:

Acrylic paint is a versatile and popular choice for painting 3D printed parts. It adheres well to various materials, including PLA and ABS, and quickly dry to a permanent finish. Acrylic paint comes in a variety of colors and finishes, making it suitable for various projects.

Enamel Paint:

Enamel paint is known for its durability and smooth finish. It provides excellent coverage and adhesion to 3D printed parts, especially those made of ABS. Enamel paints are available in a variety of colors and finishes, including glossy and matte.

Spray Paint:

Spray Paint is comfortable to cover a wide area quickly and evenly. Look for spray paints specifically formulated for plastics, as they adhere well to the surface of 3D prints. Spray paints come in a wide range of colors and finishes for different effects.

Oil-Based Paint:

Oil-based paint provides a durable and long-lasting finish for 3D printed parts. It provides excellent coverage and can be used on a variety of materials. Oil-based paints may require longer drying times compared to acrylics but offer a smooth and shiny finish.

Model Paints:

Model paints, such as those used for miniature models and hobby projects, are suitable for painting detailed and intricate designs on 3D printed parts. These paints come in a variety of colors and are formulated for precise application with fine brushes.

Water-Based Paint:

Water-based paints are environmentally friendly and easy to clean up with water. They are suitable for painting 3D printed parts made of PLA and other materials. Water-based paints dry quickly and offer good coverage.

UV Resistant Paint:

If your 3D printed parts will be exposed to sunlight or outdoor conditions, consider using UV-resistant paint to prevent fading and color degradation over time. UV-resistant paints provide added protection for outdoor applications.

Considerations When Choosing Paint:

- Material Compatibility: Ensure the paint is compatible with the material of your 3D prints, such as PLA, ABS, PETG, or others.

- Drying Time: Consider the drying time of the paint, especially if you need to apply multiple coats or work on intricate details.

- Finish: Choose a paint finish (e.g., matte, satin, glossy) that complements the desired look of your project.

By selecting a high-quality paint that suits the material of your 3D prints and meets your specific requirements, you can achieve a professional and long-lasting finish for your projects.

Can I paint 3D printed objects without primer?

While using primer is highly recommended for painting 3D printed objects, it is possible to paint 3D printed parts without using primer. However, there are some important considerations to keep in mind if you choose to skip the priming step:

Painting 3D Printed Objects Without Primer:

Surface Preparation: Without primer, the surface of the 3D printed object may not have an optimal base for the paint to adhere to. This can result in poor adhesion, uneven coverage, and a less durable finish.

Adhesion Issues: Paint applied directly to the surface of a 3D print without primer may not adhere as well, leading to peeling, chipping, or flaking over time, especially in areas with high wear or handling.

Visibility of Imperfections: Skipping the priming step may result in the visibility of layer lines, print imperfections, and rough surfaces on the painted object. Primer helps smooth out these imperfections for a more professional finish.

Color Consistency: Using primer before painting helps create a consistent base color for the paint to adhere to, especially when painting over different colored filaments or surfaces. Without primer, the underlying color or texture may affect the final paint color.

Durability: Primer provides a protective barrier between the 3D print and the paint, which can improve the durability and longevity of the painted finish. Without primer, the paint may be more susceptible to damage from handling, exposure to the elements, or other factors.

Additional Coats: Without primer, you may need to apply more coats of paint to achieve satisfactory coverage and color consistency. This can increase the time and effort required for the painting process.

Tips for Painting Without Primer:

- Clean the Surface: Ensure the 3D printed object is thoroughly cleaned and free of dust, oils, and residues before painting.

- Use High-Quality Paint: Choose a high-quality paint formulated for the material of your 3D print to improve adhesion and coverage.

- Apply Thin Coats: Apply thin, even coats of paint to reduce the risk of drips, runs, or uneven coverage.

- Allow for Sufficient Drying Time: Allow each coat of paint to dry completely before applying additional layers to prevent smudging or mixing of colors.

While it is possible to paint 3D printed objects without primer, using primer before painting is generally recommended for achieving a smoother finish, better adhesion, improved color consistency, and enhanced durability of the painted surface.

FAQ: How to Prime and Paint 3D Printed Parts

Why is it crucial to prime 3D printed components prior to painting?

Priming helps create a smooth surface on 3D printed parts by filling in imperfections and providing a better adhesion surface for paint, resulting in a more professional and durable finish.

Why are primers important when producing 3D printed parts?

Acrylic primers and filler acrylic primers are widely applied for priming 3D printed products, as they are good adherends to different materials and are capable of smoothing the roughness of layer line and defects.

How should 3D printed parts be prepared before priming?

Before priming, it is essential to clean the 3D printed parts thoroughly to remove any dust, debris, or residues. Light sanding of the surface level can also be used to enhance primer adhesion.

What painting techniques are recommended for 3D printed parts?

Spray painting with acrylic or enamel paints is often preferred for painting 3D printed parts as it provides an even and professional finish. Airbrushing can also be used for detailed work.

How long should primer be allowed to dry before painting 3D printed parts?

The drying time for primer can vary based on the type of primer used. It is suggested to comply with manufacturer recommendations but in general drying the primer for at least 24 h is recommended.

Can 3D printed parts be sanded between primer coats?

Yes, fine sanding between layers of primer can be used to produce a smoother finish by removing any flaws or roughness. Before applying more layers, scrub the surface with fine-grit sandpaper and clean the surface by removing particles.

What are some tips for achieving a professional paint finish on 3D printed parts?

Ventilate properly while painting, apply thin, even layers of paint, allow enough time to dry between coats, and optionally use a transparent topcoat to seal the paint and improve the quality of the new finish.

How can one prevent paint from pooling or dripping on 3D printed parts?

In order to avoid paint spillage or dripping, apply paint evenly, in thin layers, in a well-ventilated room and paint evenly applying smooth strokes. Avoid over-spraying or applying too much paint at once.

Are there special factors to take into account when painting 3D printing materials in general?

Yes, there may be the need to use specific primers or paints for different materials, such as PLA, ABS, PETG or resin. Testing the suitability of paints and primers for the chosen 3D printing substrate is strongly desirable.

Can 3D printed components be sprayed with metallic or patterned finishes?

That the metallic paint or texture film can be applied to the 3D printed articles to get special effects is confirmed. The surfaces can be experimentally changed by using various finishes, which is able to improve the visual appearance of these parts.