Bed temperature is essential in 3D printing to help achieve correct adhesion and stability of the object being printed. Temperature is among the most significant parameters to achieve success in 3D printing. Not only does it affect material reactivity (e.g., resin), but also energy usage for curing or solidifying. The hard resin is more reactive (and therefore less viscous) than the soft resin and thus can be cured more quickly (and with less energy). This is particularly important under ambient temperature dynamic conditions since they directly affect the exposure time needed for optimal results.

Table of Contents

Here is a detailed discussion on how bed temperature affects 3D prints:

Effects of Bed Temperature on 3D Prints:

Adhesion:

- Low Bed Temperature: If the bed temperature is too low, the initial layers of the print will not stick to the build surface effectively, causing poor adhesion and warping or detachment during the print.

- High Bed Temperature: A bed temperature that is too high will cause too much melting of the first few layers, which will give a messy print or be difficult to remove the print after it is finished.

Warping and Lifting:

- Low Bed Temperature: If the bed temperature is low, the edges of the print can warp or lift while printing, particularly for warping-prone materials such as ABS. This can result in print failure or deformation.

- Bed temperature too high: This is also a cause of warping since the bottom layers of the print can get too soft and create distortion or corner lifting.

Print Quality and Surface Finish:

Ideal Bed Temperature: Keeping the bed at its ideal temperature ensures that the layers print well and the print quality is good. It can also lead to a better surface finish and better dimensional accuracy.

Material Adhesion and Shrinkage:

Bed Temperature Material Matching Requirements: Various 3D printing materials require certain bed temperature settings for better adhesion and reduced shrinkage. Bed temperature has to be adjusted based on the material being used for successful prints.

Print Stability and Support:

Bed Temperature for Support Structures: A solid bed temperature helps ensure stable support structures while printing and assists in holding complex or overhanging sections of the print together.

Printing Speed and Efficiency:

Balanced Bed Temperature: A balanced bed temperature can increase print speed and productivity by minimizing print failure, reprints, or mid-print interruption caused by adhesion failure or warping.

Tips for Adjusting Bed Temperature:

1- Pay attention to Material Instructions

Employ the suggested bed temperature range given by the maker of the filament for the material being printed.

2- Bed Surface and Adhesion Aids:

Try to utilize bed adhesion accessories like glue sticks, painter’s tape, or custom bed surfaces to enhance adhesion, particularly for plastics such as ABS.

3- Bed Leveling:

The bed must be properly leveled to ensure an even distance from the nozzle to the bed surface, which could influence the effectiveness of bed heating.

4- Experiment and Calibration:

Create calibration prints and experiments to find the best bed temperature for your particular printer, filament, and print settings.

5- Monitor Prints:

Monitor the initial layers of the print for warping and adhesion problems and modify the bed temperature as necessary.

By knowing how bed temperature affects 3D prints and utilizing the appropriate temperature levels according to the printing material and specifications, you can enhance print quality, adhesion, and overall success rates in 3D printing activities.

PLA Filament for 3D Printing

PLA filament (Polylactic Acid) is one of the most popular and widely demanded 3D printing materials because it’s easy to work with, versatile, and eco-friendly. Following is a general introduction to PLA filament for 3D printing:

Properties of PLA Filament:

Check the most important properties of PLA filament. This includes a high shiny saturated colour, low-feeding, less odor during printing.

states that many types of 3D printers are compatible because PLA requires a heated bed.

Benefits of PLA Filament:

Advantages of using PLA filament, including its simple printing process, low warping, and how it is beginner- and school-friendly, are presented.

Highlight its broad availability, affordability, and compatibility with a diverse range of 3D printing machinery.

Print Settings and Recommendations:

Provide guidelines on best printing settings for PLA filament that include temperatures of 190°C to 220°C and bed temperatures of 50°C to 60°C.

Discuss the ideal print speeds, cooling options, and layer heights to achieve high-quality, high-fidelity prints with PLA.

Applications of PLA Filament:

Talk about the broad range of applications of PLA filament, such as prototyping, ornaments, educational models, and functional parts (considering its brittleness weakness).

Post-Processing and Finishing Techniques:

Describe PLA prints can be post-processed, sanded, painted or polished by acetone vapor smoothing or sanding to get a smooth surface.

How PLA prints can be painted or coated for improved aesthetics and protection is discussed.

Storage and Maintenance:

Provide tips on how to store PLA filament so that its quality can be maintained, like storing it in a cool, dry location with no exposure to sunlight and in airtight containers or desiccant packets.

Specialized PLA Filament Types:

Some specialty forms of PLA filament are available in the market, including wood-filled, metal-filled, glow-in-the-dark, and color-shifting filaments, with special characteristics and applications.

Common Issues and Troubleshooting:

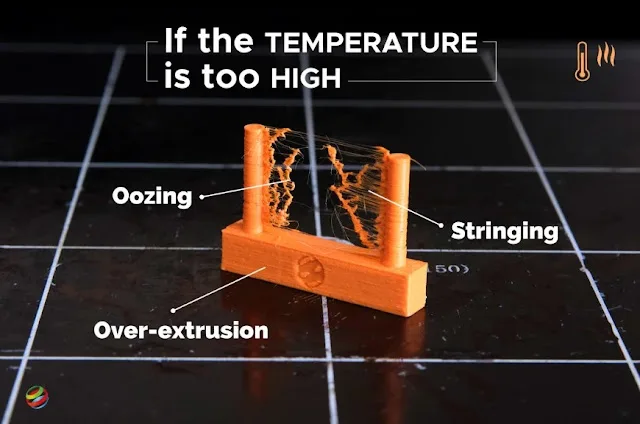

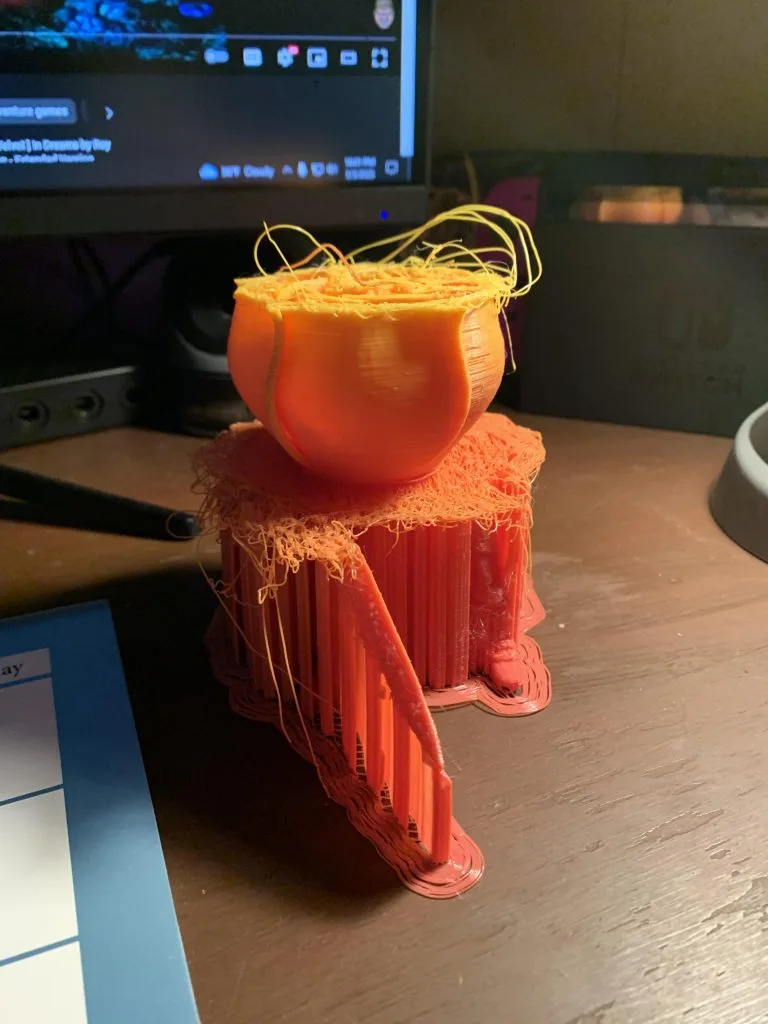

Discuss some common problems that are faced during the process of filament application, including stringing, slumping, bed adhesion failure, and overheating, along with some troubleshooting tips to overcome these difficulties.

Considerations for Choosing PLA Filament:

PLA filament-specific aspects such as filament thickness, color options, reputation of the company, eco-friendliness, print quality, and end use of printed items are also elaborated.

Bed temperature of Polylactic Acid (PLA) filament in 3D printing is a significant parameter that can significantly influence print quality, adhesion, and overall success of the printing process. Following is a step-by-step guide on how to set the correct bed temperature for PLA filament:

Setting the Bed Temperature for PLA Filament:

1. Recommended Bed Temperature Range:

The suggested bed temperature when using PLA filament is typically set from 50°C to 60°C. Due to its naturally low warping tendency, though, PLA can very often be printed successfully without a heated bed.

2. Benefits of Heating the Bed:

While PLA does not necessarily require a heated bed to print, heating the bed to a moderate value (e.g., 50°C) will increase bed adhesion, especially for large or high-surface-area prints.

3. Adhesion and Warping:

A heated bed helps the first few layers of PLA adhere well to the build surface, reducing warping, lifting, or detaching during printing. It can also help maintain uniform bed temperature during the print.

4. Large Prints and Layer Adhesion:

For big prints or ones with a large surface area, a heated bed can assist in improving layer adhesion and preventing warping, ensuring the general print stability.

5. Adjusting Bed Temperature:

If you do encounter issues with adhesion to the bed or warping, it is preferable to modify the bed temperature within the suggested parameters. Gradual changes can allow you to find the best temperature for your particular printer and PLA filament.

6. Experimentation and Calibration:

Run calibration prints and experiments to find the optimal bed temperature for your specific PLA material and print setup. Note settings that produce the most favorable outcomes so that they can be reused.

7. Room Temperature Considerations:

Room temperature and ambient conditions might influence the success of bed temperature. A controlled printing environment should be established for achieving consistent outcomes.

8. Bed Surface Compatibility:

Consider the bed surface you’re currently using (glass, PEI sheet, BuildTak, etc.) since it will influence bed adhesion and the performance of the heated bed. Different surfaces will have slight modifications to bed temperature that are required.

Conclusion:

Bed temperature modification for PLA filament to align with the suggested parameters can assist in facilitating stronger adhesion to the print bed, minimizing warping, and improving the quality of 3D printed items.

Although PLA tends to produce good print results without a heated bed, a modest bed temperature can enhance print success, particularly for larger or more intricate models. Methodical experimentation, careful calibration, and consideration of ambient temperature and the chemistry of the bed surface are paramount in determining the most appropriate bed temperature for PLA filament, thus enabling high-quality print results consistently.

What’s the best way to calibrate bed temperature for PLA?

Calibrating the bed temperature for PLA (Polylactic Acid) is critical to achieving maximum adhesion, print quality, and dimensional accuracy in 3D printing. The following is a step-by-step guide on the best approach to calibrate the bed temperature for PLA:

Steps to Calibrate Bed Temperature for PLA:

Preparation:

Keep your 3D printer in a good state, well levelled, and the build plate is clean and free of debris. Keep your printer in a well-ventilated location.

Select Test Model:

Select a calibration test model featuring a big flat surface, i.e., a calibration cube or planar test print, for verifying bed adhesion and print quality.

Initial Bed Temperature Setting:

Start with the given bed temperature range for PLA that the filament manufacturer recommends. Typically, PLA bed temperatures range between 50°C and 60°C.

Print Test Object:

Utilize the initial bed temperature setting for printing the chosen calibration test model. Monitor the initial layers closely to assess potential problems related to adhesion, warping, or lifting.

Adhesion Check:

Evaluate how well the print adheres to the bed. If the print easily detaches or shows poor adhesion, attempt to increase the bed temperature by a slight amount.

Warping Assessment:

Check the print for warping signs, with close attention to edges and corners. If warping occurs, adjust the bed temperature to minimize this effect.

Fine-Tuning:

Make small adjustments to the bed temperature, typically 5°C increments, and then re-print the test model to find the ideal temperature that promotes enough adhesion while minimizing warping.

Print Quality Inspection:

Assess the general print quality, surface finish, and dimensional accuracy of the calibration test prints at varied bed temperature settings.

Optimal Temperature Determination:

Establish a bed temperature setting that is a balance between adhesion, extremely low warping, and high print quality for the given PLA filament and printer conditions.

Record and Maintain Settings:

Document the optimal temperature for bed calibration with PLA in your 3D print settings for posterity. On a constant basis, check and adjust bed temperature when required for different PLA filament or printing conditions.

Additional Tips:

- Consider Bed Surface: The type of bed surface will also affect bed adhesion and determine bed temperature adjustments (glass, PEI sheet, BuildTak, etc.).

- Experiment with Adhesion Aids: If adhesion problems persist, try using glue sticks, hairspray, and special bed adhesive options.

- Temperature Variation: Ambient condition, which includes room temperature, may also affect bed temperature; hence, an even print environment should be maintained.

By doing so and calibrating bed temperature for PLA according to calibration test print results, it is entirely possible to fine-tune this parameter even further.

FAQ: How does Bed Temperature Affect 3D Prints

What role does bed temperature play in 3D printing?

Bed temperature is critical for adhesion, avoiding warping, and sealing the printed part into the desired object both for quality and proper polymer deposition and adhesion on each layer.

What is the relationship between bed temperature and the build plate adhesion?

The bed temperature will heat the build plate and allow good adhesion from the first layers of the print. Different materials benefit from specific bed temperatures for optimal adhesion.

Why is bed temperature critical for avoiding warping in 3D printing?

An optimal temperature of the bed assures uniform cooling of the material, thus relieving the printed part from thermal stress and withstanding warping or lifting of the print part while at the printing phase.

Under what bed temperature conditions do the various filament types, namely PLA, ABS, and PETG, perform best?

However, PLA required relatively lower bed temperatures (50 to 60 degrees C) in contrast to those required by ABS (90-110 degrees C) or PETG (80-90 degrees C) based on having different thermal properties.

Why is it wrong to use the wrong bed temperatures in 3D printing?

Wrongly set bed temperature values can cause poor adhesion or even warping or delamination of prints, or even a total failure of the prints, thus compromising overall quality and success of the printing process.

To which extent is bed temperature adjustable and optimal for various materials?

You can use filament-specific settings or the manufacturer’s recommendations to guide you in determining the best bed temperature for each filament type. For best results, you may need some extra testing and calibration.

There are safety implications in modifying bed temperature during 3D printing.

When adjusting the bed temperature, please ensure the printing environment is well ventilated and abide by all the safety instructions of the printer manufacturer to prevent any overheating or risk of damage.

What are some troubleshooting steps that can be taken if bed temperature problems occur during 3D printing?

In case there are problems with the bed temperature running around poor adhesion or warping, some troubleshooting steps that can be taken include: Recalibrating the bed temperature settings; Checking that the bed is level; and Lowering the print speed as well as the cooling settings.