A Deep Dive into How 3D Printing Works

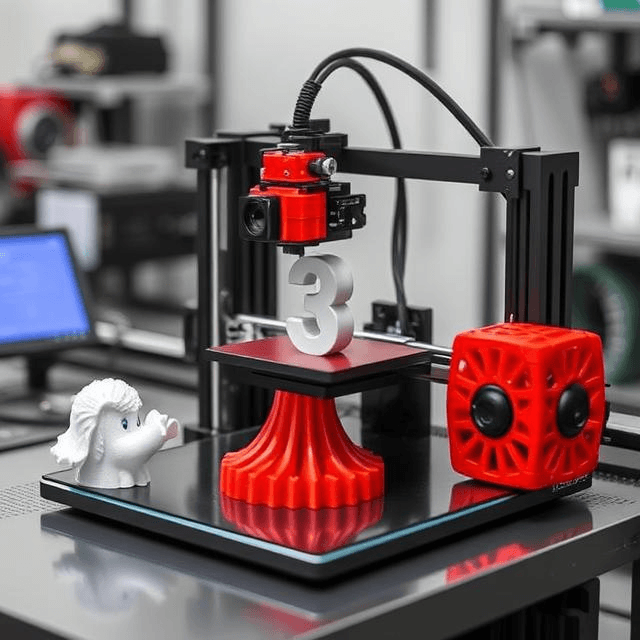

3D printing has emerged as one of the most exciting technological innovations of the 21st century. It has transformed industries, from manufacturing and automotive to medicine and fashion. But how does 3D printing work, and why is it gaining so much popularity?

In this comprehensive guide, we will explore the fundamentals of 3D printing, break down the different types of 3D printers and technologies, and explain how the process works step by step. Whether you’re new to 3D printing or looking to enhance your knowledge, this article will provide you with all the essential details.

Table of Contents

How Does 3D Printing Work? :

The process of 3D printing involves several key steps, from creating a 3D model to finalizing the printed object. Let’s explore these steps in detail.

1. Designing the 3D Model :

The first step in the 3D printing process is creating a 3D model. This is typically done using Computer-Aided Design (CAD) software, where the designer creates a virtual representation of the object.

- Software Tools for Designing:

- AutoCAD

- Fusion 360

- TinkerCAD (great for beginners)

- Blender (used for artistic designs)

Once the design is complete, the file is exported as an STL (stereolithography) or OBJ file format, which is compatible with most 3D printers.

2. Slicing the 3D Model :

After the 3D model is created, it needs to be sliced into thin layers. This process is done using slicing software, such as Cura, PrusaSlicer, or Simplify3D. The slicing software converts the 3D model into instructions for the printer, specifying the path the printer’s nozzle should follow and how each layer of material should be deposited.

- Common Slicing Settings:

- Layer height (thickness of each layer)

- Print speed

- Temperature settings

- Infill density (how much material to use inside the print)

- Support structures for overhangs

3. Preparing the Printer :

Once the 3D model is sliced, it’s time to prepare the 3D printer. This includes loading the chosen material (filament or resin), calibrating the printer’s bed and nozzle, and ensuring the printer’s settings match the specifications of the sliced model.

- Key Printer Components:

- Print bed (platform where the object is printed)

- Hotend (extruder nozzle that melts the material)

- Stepper motors (to control movement along the X, Y, and Z axes)

- Cooling fans (to control the cooling rate of the material)

4. Printing the Object :

Now comes the exciting part—printing the object! The printer begins to heat up the material and deposit it layer by layer. The printer follows the instructions generated by the slicing software to precisely build the object.

- Printing Process Steps:

- The printer heats the extruder to the appropriate temperature for the selected material.

- The filament or resin is extruded through the nozzle.

- The printer starts laying down the first layer, which sticks to the print bed.

- Each subsequent layer is deposited on top of the previous one until the object is complete.

5. Post-Processing :

After the print is complete, the object may require some post-processing. This could involve removing support structures, sanding rough surfaces, or curing the print (in the case of resin prints).

- Common Post-Processing Techniques:

- Support Removal: Supports help hold overhangs in place during printing but need to be carefully removed.

- Sanding and Smoothing: Smooth out rough areas for a polished finish.

- Curing (for Resin Prints): Resin prints often require additional curing under UV light to harden fully.

Types of 3D Printing Technologies :

There are several different types of 3D printing technologies, each with its own strengths, weaknesses, and applications. Below, we’ll discuss the most common 3D printing methods.

1. Fused Deposition Modeling (FDM) :

FDM is the most common and affordable 3D printing method. It works by heating a filament (usually PLA, ABS, or PETG) and extruding it through a nozzle to build the object layer by layer.

- Advantages: Affordable, wide variety of materials, easy to use.

- Disadvantages: Can produce visible layer lines and may not offer the highest resolution.

2. Stereolithography (SLA) :

SLA uses a laser to cure liquid resin, layer by layer, to build the object. It is known for producing high-precision prints with smooth finishes.

- Advantages: High resolution, smooth finish.

- Disadvantages: Expensive, requires post-curing.

3. Selective Laser Sintering (SLS) :

SLS uses a laser to fuse powdered material (usually nylon or metal) into solid layers. It’s commonly used for industrial applications and creating functional prototypes.

- Advantages: No need for support structures, high durability.

- Disadvantages: Expensive, requires post-processing.

4. Digital Light Processing (DLP) :

DLP is similar to SLA but uses a projector to cure resin, instead of a laser. It’s often faster than SLA due to its ability to cure an entire layer at once.

- Advantages: Faster printing than SLA, high resolution.

- Disadvantages: Limited to smaller prints.

Materials Used in 3D Printing :

The type of material you use for 3D printing can significantly impact the quality, durability, and cost of the printed object. Here are some common materials used in 3D printing:

1. PLA (Polylactic Acid) :

PLA is one of the most popular 3D printing materials, known for its ease of use and low odor. It’s biodegradable and available in various colors.

- Applications: Prototypes, figurines, toys, educational models.

2. ABS (Acrylonitrile Butadiene Styrene) :

ABS is a strong, heat-resistant plastic commonly used in automotive and industrial applications. It’s more challenging to print with than PLA due to warping.

- Applications: Functional parts, automotive components, tools.

3. PETG (Polyethylene Terephthalate Glycol) :

PETG is a flexible and durable material that combines the strength of ABS with the ease of use of PLA. It is resistant to moisture and UV light.

- Applications: Food containers, protective components, and mechanical parts.

4. Resin :

Resin is used in SLA and DLP 3D printers. It comes in various formulations, including standard, tough, flexible, and castable resins.

- Applications: Jewelry, dental products, and high-precision models.

Applications of 3D Printing :

3D printing is used in a wide range of industries. Below are some notable applications:

1. Prototyping :

3D printing is widely used for rapid prototyping. Designers and engineers can quickly create physical models of their designs, test them, and make improvements before manufacturing the final product.

2. Healthcare :

In healthcare, 3D printing is used to create custom implants, prosthetics, and even human tissue. The ability to print highly specific medical devices or models allows for more personalized treatment.

3. Manufacturing :

Many manufacturers use 3D printing to produce low-volume parts, tools, and even end-use products. This is especially valuable in industries where custom or small-batch production is required.

4. Architecture and Construction :

3D printing has found its place in architecture, with printers creating scale models and even entire buildings. Construction companies have used 3D printing to create concrete structures on-site.

Conclusion :

3D printing is an exciting and transformative technology that has revolutionized industries around the world. From prototyping to manufacturing, healthcare to construction, 3D printing offers unparalleled possibilities. By understanding the process and technologies involved, you can harness the power of 3D printing for your own projects and innovations.

As the technology continues to evolve, the applications and materials for 3D printing will expand, making it an essential tool for both professionals and hobbyists alike. Whether you’re designing a custom prototype or creating a fully functional part, 3D printing has something to offer everyone.

FAQ: How Does 3D Printing Work?

What Are the Different 3D Printing Technologies?

Common 3D printing technologies include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Digital Light Processing (DLP), each with its unique approach to layering materials.

What Are the Limitations of 3D Printing?

Limitations of 3D printing include slower production speeds compared to traditional manufacturing, limitations in material properties, post-processing requirements for certain prints, and the need for skilled design and printing expertise.

Is it hard to learn 3D printing?

Although it can be a little difficult for a novice, learning 3D printing is not impossible. You can quickly become proficient in 3D printing with a little perseverance and practice.