It is important to clean and reclaiming screen printing screens correctly to have high-quality prints and extend the life of your materials. You are a new or experienced printer, but proper methods and supplies will save you time, energy, and money. In this guide, we will walk you through the best methods, tools, and cleaning chemicals to keep your screens performing at their optimal level.

Table of Contents

Why Cleaning and Reclaiming Screens is Important

1. Extends the Life of Screens

Emulsion and dried ink will degrade the mesh over time, lowering its performance. Regular cleaning prevents the accumulation and makes your screens last longer in production.

2. Improves Print Quality

Clogged and dirty screens result in poor ink transfer and printing unevenness. A clean screen ensures crisp, consistent prints.

3. Saves Money on Supplies

Reclaiming screens spares you from purchasing frames and mesh repeatedly.

4. Ensures Eco-Friendly Printing

Proper cleaning and reclaiming practices avert excessive waste and the use of dangerous chemicals, resulting in a more environmentally friendly printing process.

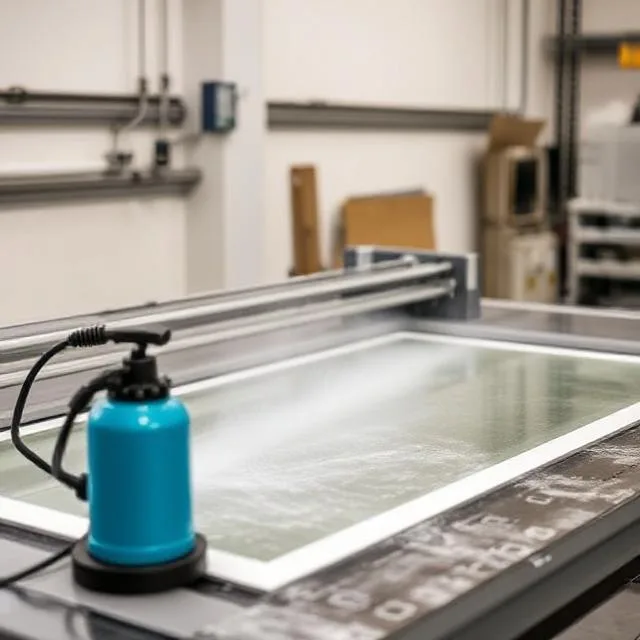

Basic Tools and Supplies Required for Cleaning and Reclaiming

Before starting the cleaning process, ensure you have the necessary tools and supplies:

1. Cleaning Solutions

- Emulsion Remover – Dissolves stencil emulsion.

- Ink Remover – Dissolves leftover ink from the mesh.

- Degreaser – Removes oils and residue, allowing for good adhesion for the next print job.

- Haze Remover – Eliminates ghost images from previous prints.

2. Cleaning Equipment

- Pressure Washer – Helps strip dried ink and emulsion.

- Scrub Brushes – For the application of cleaning solutions.

- Washout Booth – An enclosed area for cleaning screens effectively.

- Protective Gear – Gloves, goggles, and masks for the safe handling of chemicals.

3. Additional Supplies

- Squeegees – To remove excess liquids from the screen.

- Lint-Free Rags – For wiping down and drying screens.

- Plastic Scrapers – Helps remove hardened ink before using liquid cleaners.

Step-by-Step Guide to Cleaning Screen Printing Screens

Step 1: Removing Excess Ink

- Use a plastic scraper or spatula to remove as much ink as possible.

- Wipe off the remaining ink using a lint-free rag or paper towel.

- Dispose of ink properly to avoid environmental contamination.

Step 2: Applying Ink Remover

- Spray or apply ink remover to both sides of the screen.

- Let it sit for a few minutes to break down ink residue.

- Scrub with a soft-bristled brush and rinse with water.

Step 3: Removing Emulsion

- Spray or pour emulsion remover onto the screen.

- Wait 30 seconds to 1 minute (don’t let it dry).

- Scrub the screen gently using a brush.

- Wash out the emulsion completely with a pressure washer.

Step 4: Eliminating Stains and Ghost Images

- Apply haze remover if the screen still has ghost images.

- Scrub gently and rinse thoroughly with water.

Step 5: Degreasing the Screen

- Apply degreaser to remove any remaining residues.

- Rinse well and dry the screen thoroughly before reuse.

Best Practices for Screen Maintenance

To keep your screens in great condition, follow the best practices below:

1. Clean Screens As Soon As Possible After Use

Ink and emulsion are harder to clean when dry, so clean screens as soon as possible after printing.

2. Use Proper Cleaning Products

Avoid using household cleaners that will damage the mesh and frame.

3. Store Screens Properly

Store screens in a dry, dust-free area to prevent contamination.

4. Rotate Screens on a Regular Basis

Using multiple screens for multiple designs reduces wear and tear on any single screen.

5. Guard Screens when Storing

Use plastic covers or racks to protect against accidental damage.

Conclusion

Screen cleaning and reclaiming is an important aspect of running a high-quality print business. With the proper equipment and methods, you can prolong the life of your screens, enhance print quality, and save money. Implement these best practices into your workflow to keep your printing business running smoothly and in an environmentally conscious manner.